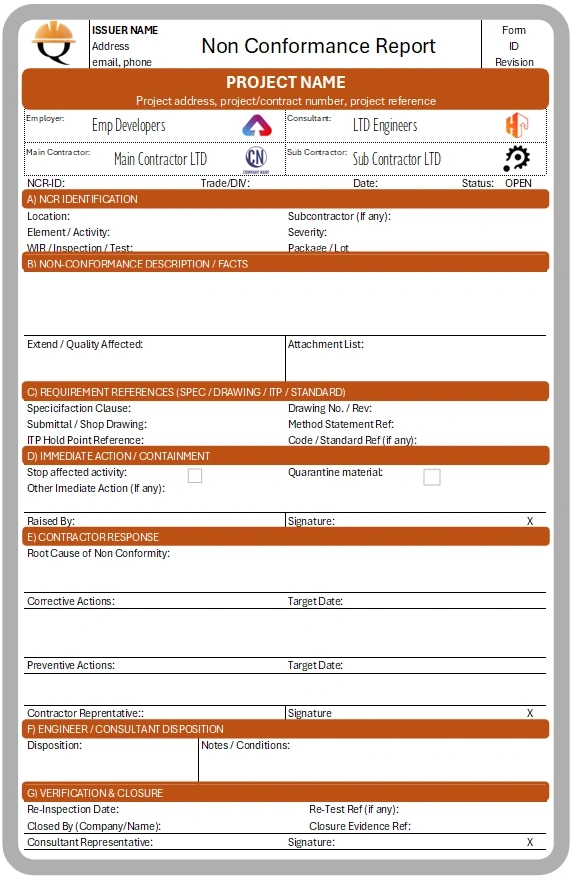

NCR Form Template

Use this NCR (Non-Conformance Report) form template to record and close construction non-conformances consistently, with the minimum fields expected by most QA/QC systems.

Best use: site QA/QC teams, consultants, and contractors who need a clean NCR format with clear references and closure evidence.

Download NCR Form Template

What this NCR form includes (fields)

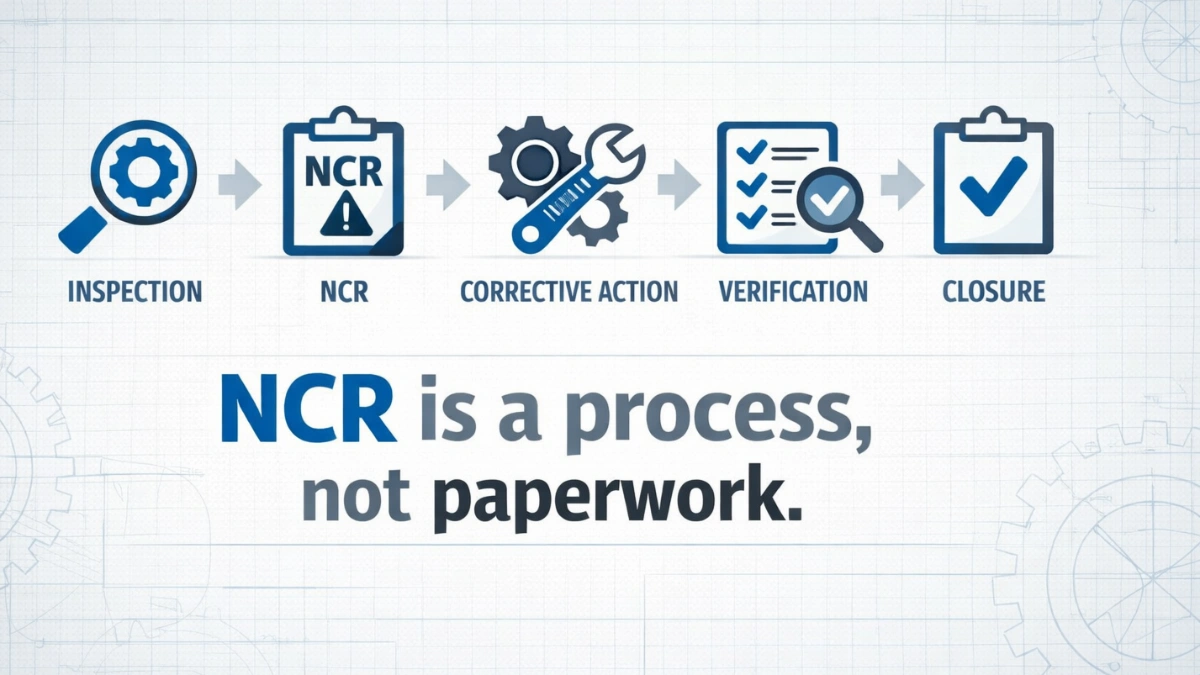

Need the definition and workflow? Read NCR Meaning in Construction (when to issue an NCR, who fills each section, and how NCRs are closed).

A) NCR identification

-

Project / package / contract

-

NCR number (unique reference)

-

Date raised

-

Raised by (company + name)

-

Responsible party (main contractor / subcontractor)

B) Location & work description

-

Building / zone / gridline / level / chainage

-

Trade / discipline (civil, architectural, MEP, steel, etc.)

-

Activity / element (slab, column, waterproofing, cable pulling, etc.)

C) Non-conformance description (facts only)

-

What was found (measured/observed/test result)

-

Quantity/extent (how much area affected)

-

Evidence reference (photos, sketches, marked-up drawings)

D) Requirement references (the most important part)

-

Specification section / clause

-

Drawing number + revision

-

Approved shop drawing / method statement reference

-

ITP step / WIR reference (if applicable)

-

Standard/code reference (if applicable)

E) Immediate action / containment

-

Stop affected activity (Yes/No)

-

Quarantine material (Yes/No)

-

Protect from concealment (Yes/No)

-

Temporary measures implemented

F) Contractor response

-

Root cause (why it happened)

-

Corrective action (how it will be fixed)

-

Preventive action (how recurrence is prevented)

-

Target dates

G) Engineer / Consultant disposition

-

Accept as-is (with justification)

-

Repair

-

Remove and replace

-

Accept with concession / technical deviation (if allowed)

H) Verification & closure

-

Re-inspection date

-

Re-test results reference (if applicable)

-

Closure evidence attached (photos/reports)

-

Closed by + date + signature

How to fill an NCR (quick guidance)

-

Write the non-conformance as a measurable fact (not an opinion).

-

Always include at least one hard reference: spec clause or drawing number.

-

Record containment actions immediately (stop/quarantine/protect).

-

Require contractor response with root cause + corrective + preventive action.

-

Close only after verification evidence is submitted and accepted.

Suggested numbering system (simple and scalable)

Use one consistent format, for example:

NCR-Discipline-Year-Sequential

-

NCR-CIV-2026-001

-

NCR-MEP-2026-014

If you manage multiple packages, add package code:

-

NCR-PKG1-CIV-2026-001

Common mistakes (avoid these)

-

No reference to specs/drawings (“not acceptable” is not enough)

-

Closing without evidence

-

Using NCRs for minor snags (creates noise and weakens the system)

-

Not controlling the affected work/material (containment)

Related pages (published separately)

-

NCR Meaning in Construction

-

NCR Log Template (Register)

-

Observation vs NCR vs Snag vs Defect

Filled Example NCR (Concrete Works)

A) NCR identification

-

Project: ABC Residential Towers – Package 01

-

NCR No.: NCR-CIV-2026-003

-

Date raised: 06 Jan 2026

-

Raised by: Consultant QA/QC Engineer

-

Responsible party: Main Contractor / RC Subcontractor

B) Location & work description

-

Location: Tower A, Level 05, Grid B-4 to B-6

-

Discipline / Trade: Civil / Reinforced Concrete

-

Element / Activity: Reinforcement fixing for slab S5 prior to concrete pour

C) Non-conformance description (facts only)

During pre-pour inspection, the top reinforcement spacing in the slab strip at Grid B-4 to B-6 was measured at 250 mm c/c, whereas the approved drawing requires 200 mm c/c. The affected area is approximately 18 m².

Evidence: Photo refs NCR-CIV-2026-003-01 to 05 and marked-up sketch SK-NCR-003.

D) Requirement references

-

Structural drawing: S-105 Rev 04 (Top reinforcement spacing @ slab strip = 200 mm c/c)

-

Specification: Section 03 30 00 – Cast-in-Place Concrete, clause (reinforcement installation per drawings)

-

ITP: ITP-RC-01, Hold Point HP-03 (Pre-pour rebar inspection)

-

WIR: WIR-RC-05-147 (submitted for pre-pour inspection)

E) Immediate action / containment

-

Stop affected activity: YES (pour not permitted in affected zone)

-

Prevent concealment: YES (do not place concrete until clearance)

-

Quarantine material: N/A

-

Temporary measures: Affected area tagged and barricaded; foreman instructed not to proceed.

F) Contractor response (root cause + corrective + preventive)

-

Root cause: Fixing crew used an outdated rebar spacing note from an earlier revision and the supervisor did not verify against the latest approved drawing revision.

-

Corrective action: Remove and re-fix top reinforcement in the affected zone to 200 mm c/c as per S-105 Rev 04. Submit re-inspection request.

-

Preventive action: Toolbox talk for rebar crew; supervisor to verify drawing revision on site before start of fixing; drawing revision list to be posted in the rebar yard.

-

Target date: Corrective action completed by 07 Jan 2026; re-inspection on 07 Jan 2026.

G) Engineer / Consultant disposition

-

Disposition: Repair / Rectify

-

Notes: Works may proceed only after re-inspection and acceptance of corrected spacing. No concrete placement permitted in affected zone prior to clearance.

H) Verification & closure

-

Re-inspection date: 07 Jan 2026

-

Verification outcome: Spacing re-measured at 200 mm c/c; accepted.

-

Closure evidence: Photo refs NCR-CIV-2026-003-C1 to C3; updated marked-up sketch attached.

-

NCR status: CLOSED

-

Closed by: Consultant QA/QC Engineer – 07 Jan 2026