NCR Meaning in Construction

Quick meaning (construction QA/QC)

NCR in construction means Non-Conformance Report (also written Nonconformance Report).

It is a formal QA/QC record raised when work, materials, testing, or documentation does not comply with project requirements.

Note: “NCR” has other meanings in other industries. This page is strictly about construction quality (QA/QC). It’s also commonly mistyped as “NRC”.

One-sentence definition

An NCR (Non-Conformance Report) is a controlled QA/QC document used to identify, contain, correct, verify, and close a confirmed case of non-compliance with contract specifications, approved drawings, method statements, ITPs, or applicable standards.

Common alternative names (same concept)

On different projects/clients, NCR may be called:

-

Nonconformance Report

-

Non-Conformity Report

-

Non-Conformance Notice

-

Non-Compliance Notice (NCN)

-

Defect / Defective Work Notice (often contractual wording)

-

Rejection Notice (materials/work rejection)

-

Corrective Action Request (CAR) (sometimes separate, sometimes merged)

What triggers an NCR (typical causes)

An NCR is typically raised after confirmed non-compliance, such as:

1) Failed test

Examples:

-

concrete strength result below requirement

-

weld NDT rejection

-

pressure test failure

-

soil compaction below spec

2) Rejected inspection

Examples:

-

installation not per approved drawing

-

tolerance exceeded

-

wrong material used

-

work executed without required inspection hold point

3) Unauthorized deviation

Examples:

-

change in rebar size/spacing without approval

-

unapproved material substitution

-

method statement not followed in a way that affects compliance

4) Missing mandatory records

Examples:

-

inspection not performed and work is already covered

-

required test missing or invalid

-

traceability certificates not available where required

What an NCR is NOT (to prevent misuse)

-

Not a snag list / punch list item (usually minor completion/finishing)

-

Not a “general complaint” document

-

Not automatically a dispute or claim

-

Not proof of fault by itself (it’s a record of non-compliance and required actions)

Who issues NCRs on a project

Depending on project structure, NCRs may be issued by:

-

Consultant / Engineer / Supervision team (most common externally)

-

Contractor QA/QC (internal NCRs for control before consultant action)

-

Client representative (less common; often via consultant)

Regardless of issuer, the contractor is typically required to respond, implement corrective action, and provide closure evidence.

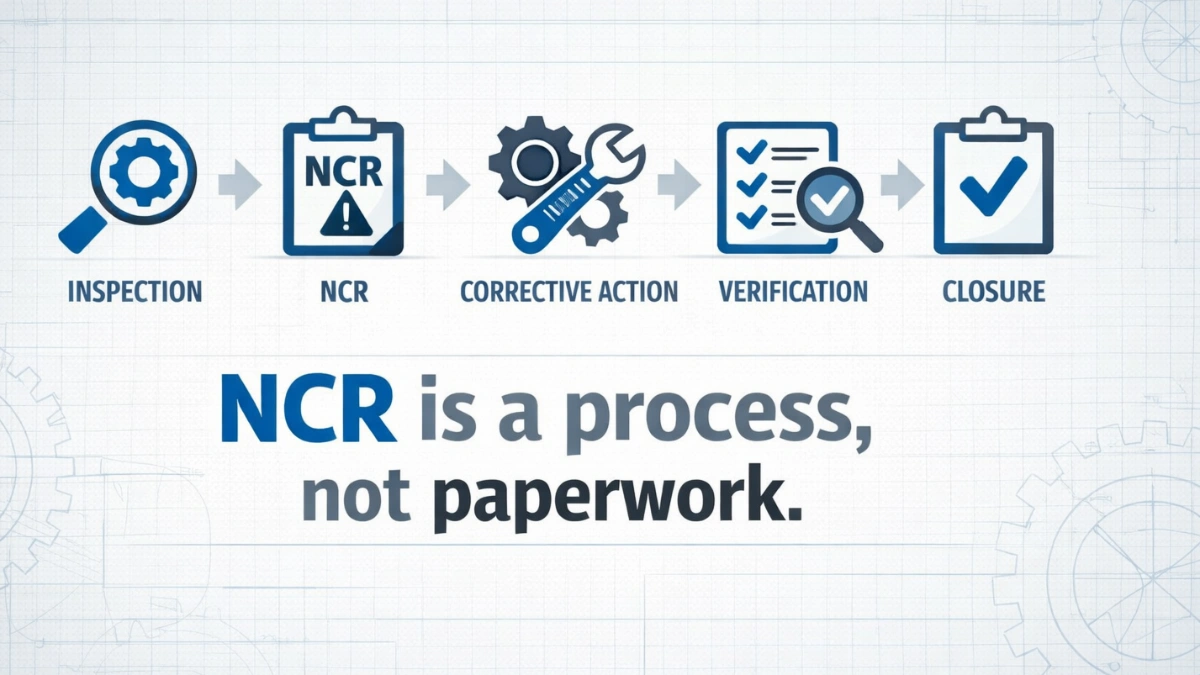

Standard NCR workflow (from issue to closure)

A construction NCR generally follows this lifecycle:

-

Identify non-conformance (inspection/test/audit/site finding)

-

Record facts + location + references (drawing/spec/ITP)

-

Containment (stop affected activity, quarantine material, prevent concealment)

-

Contractor response

-

root cause (why it happened)

-

corrective action (how to fix this case)

-

preventive action (how to prevent recurrence)

-

-

Disposition by Engineer/Consultant

-

accept as-is (rare, with justification)

-

repair

-

remove and replace

-

accept with concession/technical deviation (if allowed)

-

-

Verification

-

re-inspection / re-test

-

evidence submitted (photos, reports, results)

-

-

Close NCR

-

signed, dated, status updated in the register/log

-

What “good” NCR writing looks like (minimum standard)

A strong NCR statement is:

-

factual (no opinions, no blame language)

-

specific (exact location, element, trade)

-

referenced (spec clause, drawing number, ITP step)

-

verifiable (photos, measurements, test report IDs)

Bad: “Work is not acceptable.”

Good: “Rebar spacing at Grid B-4 measured at 250 mm vs drawing S-103 requirement 200 mm; area inspected on 2026-01-06; photos ref NCR-P-014-01 to 03.”

Why NCRs matter (practical value)

A functioning NCR system:

-

prevents unsafe continuation of works

-

reduces rework through early detection

-

improves quality performance through corrective/preventive action

-

protects handover documentation

-

creates defensible records for disputes (when needed)

Upcoming NCR pages in this series

You’ll publish tool-first pages and focused info pages. Each page will address one intent:

-

NCR Log / Register (Tool): tracking status, ageing, and closure

-

Observation vs NCR vs Snag vs Defect (Info): when to use each record

-

When to Issue an NCR (Info): failed tests, rejected inspections, missing records

-

NCR Severity Matrix (Tool): minor/major/critical classification

-

Notice to Correct Letter (Tool): contractual escalation template

-

Proceed at Contractor’s Risk Letter (Tool): conditional continuation template

-

Continue Work with an Open NCR? (Info): stop-work vs proceed-at-risk logic

-

Can an NCR Lead to Termination? (Info): default, notices, and time limits

-

Open NCRs at Handover (Info): taking-over and defects implications

Summary

-

Term: NCR

-

Meaning (construction): Non-Conformance Report

-

Purpose: control confirmed non-compliance (identify → correct → verify → close)

-

Triggers: failed test, rejected inspection, unauthorized deviation, missing mandatory record

-

Key fields: description + location + requirement reference + corrective action + verification evidence + closure

-

Not: snag list, generic complaint, automatic claim