Review or Prepare Incident Reports and Implement Corrective Actions in Construction Safety

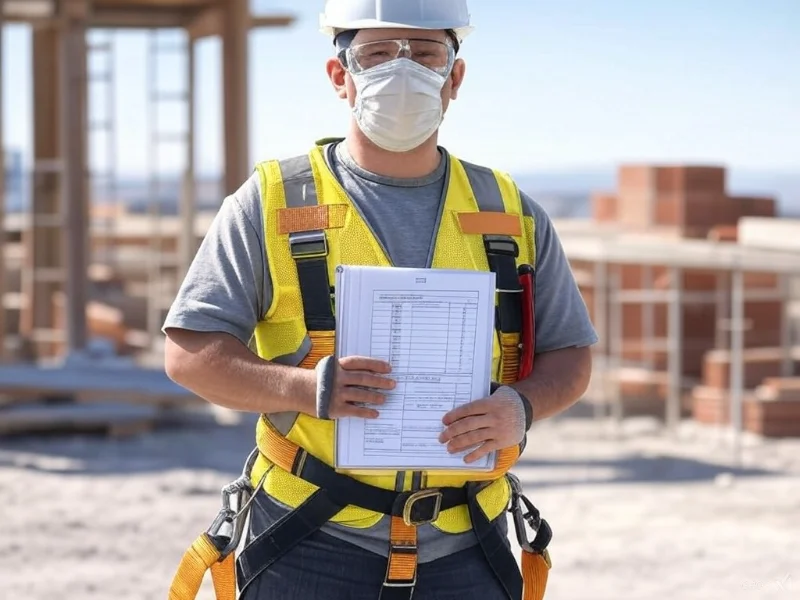

Ensuring safety on construction sites is paramount. Acritical component of maintaining a safe environment is the systematic review of incident reports and the implementation of corrective actions. This process not only addresses immediate safety concerns but also fosters a culture of continuous improvement.

Understanding the Importance of Incident Reviews and Corrective Actions

Regularly analyzing incident reports helps in identifying patterns and root causes of safety issues. By addressing these underlying causes, construction companies can prevent future occurrences and enhance overall safety protocols. The Occupational Safety and Health Administration(OSHA) emphasizes the necessity of investigating incidents to uncover root causes and develop effective corrective actions.

OSHA

Steps to Conduct a Comprehensive Incident Review

-

Prompt Reporting and Documentation

: Ensure all incidents, including near misses, are reported immediately. Detailed documentation should include the who, what, when, where, and how of the incident.

-

Thorough Investigation

: Assemble a team to investigate the incident, focusing on identifying root causes rather than assigning blame. This involves collecting evidence, interviewing witnesses, and analyzing the sequence of events.

-

Develop Corrective Actions

: Based on the findings, implement corrective actions aimed at eliminating identified hazards. This could involve revising safety protocols, providing additional training, or upgrading equipment.

-

Monitor and Review

: After implementing corrective actions, monitor their effectiveness. Regularly review incident reports to ensure that similar issues do not recur.

Utilizing Checklists for Enhanced Safety Compliance

Incorporating safety checklists into daily operations ensures consistent adherence to safety standards. Checklists serve as practical tools to verify compliance and identify potential hazards before they result in incidents. Quollnet provides several checklists.

A. Daily Safety Checklists:

-

PPE (helmets, gloves, harnesses, boots) inspection

-

Site housekeeping (removal of debris, clear walkways)

-

Functionality of tools and equipment

-

Verification of safety signage and emergency exits

-

Fire hazard inspection (flammable materials, extinguisher accessibility)

B. Weekly Safety Checklists:

-

Heavy machinery and crane inspections

-

Scaffolding and ladder integrity

-

Electrical wiring and fire safety compliance

-

Worker training and safety briefing updates

- Availabilityand condition of first aid supplies

Conclusion

Regularly reviewing incident reports and implementing corrective actions are vital practices for maintaining a safe construction environment. By systematically investigating incidents and utilizing tools like safety checklists, construction companies can proactively address potential hazards and foster a culture of safety. It's imperative to integrate these practices into daily operations to protect workers and ensure project success.

Downloadable Resource

- Incident Report and Corrective Action Template Word: incident report corrective actions construction template safety download

- Incident Report and Corrective Action Template PDF : incident report corrective actions construction template safety download

References

-

Occupational Safety and Health Administration. (n.d.).

Incident Investigation

. Retrieved from

https://www.osha.gov/incident-investigation

-

Center for Construction Research and Training. (n.d.).

Construction Safety Checklist

. Retrieved from

https://www.cpwr.com/wp-content/uploads/ConstructionSafetyChecklist_English.pdf

-

North Carolina Department of Labor. (n.d.).

Construction Safety Inspection Checklists

. Retrieved from

https://www.labor.nc.gov/documents/construction-safety-inspection-checklists

-

Occupational Safety and Health Administration. (n.d.).

Recommended Practices for Safety and Health Programs in Construction

. Retrieved from

https://www.osha.gov/sites/default/files/publications/OSHA3886.pdf

By following these guidelines and utilizing the provided resources, construction professionals can enhance safety standards and contribute to a safer working environment.