Optimized Daily PPE Inspection Checklist

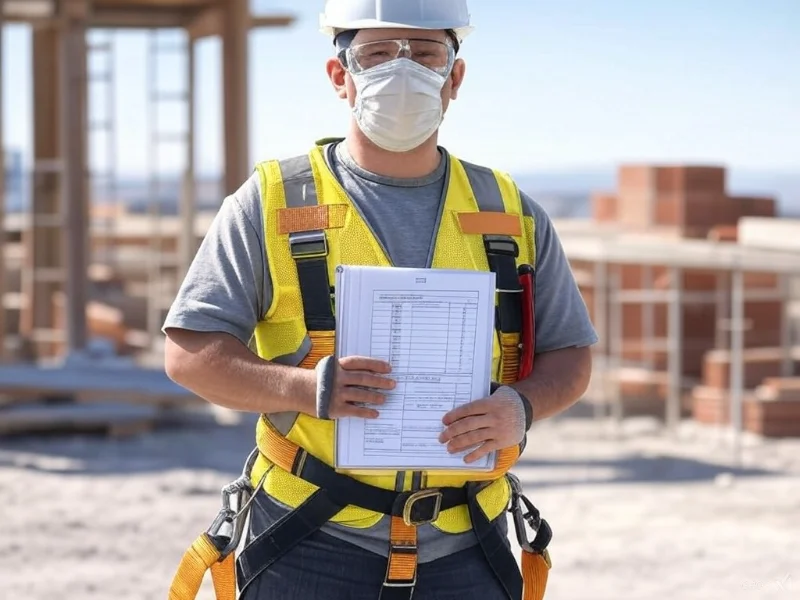

In the realm of workplace safety, an optimized daily Personal Protective Equipment (PPE) inspection process is paramount. Regular inspections not only ensure compliance with safety regulations but also significantly reduce the risk of workplace injuries. By integrating digital solutions and fostering a proactive safety culture, organizations can enhance the effectiveness of their PPE inspection protocols.

The Importance of Daily PPE Inspections

Daily PPE inspections serve as the first line of defense against potential hazards. They ensure that equipment such as hard hats, safety glasses, gloves, and high-visibility vests are in optimal condition, thereby safeguarding workers from injuries. Regular checks also help in identifying wear and tear early, preventing equipment failure during critical operations. QuollNet , advancedtech.com

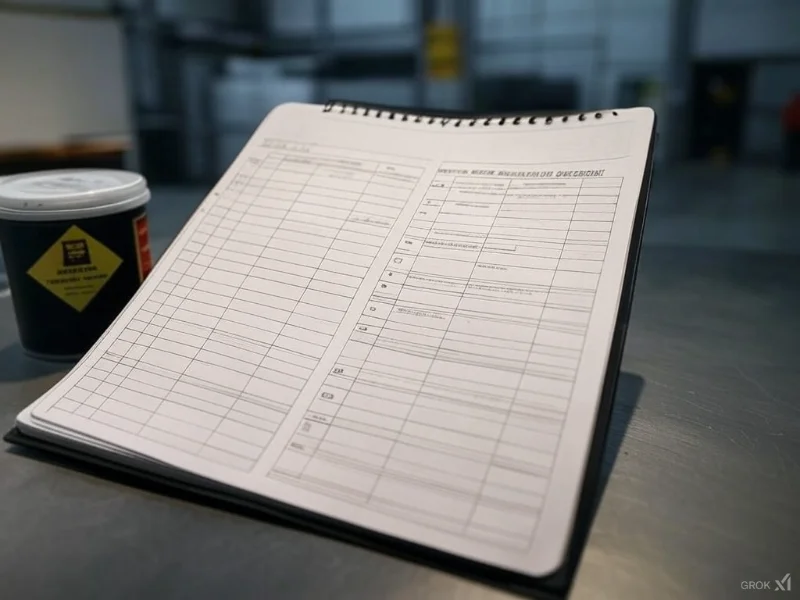

Challenges in Traditional PPE Inspection Methods

Traditional paper-based inspection methods often face challenges such as inconsistent record-keeping, delayed reporting, and difficulty in tracking compliance. These issues can lead to overlooked safety hazards and increased risk of accidents. Moreover, manual processes are time-consuming and prone to human error, making it challenging to maintain a consistent safety standard across the organization. blog.glartek.com, Manifest

Digital Transformation: Enhancing PPE Inspections

Embracing digital solutions can revolutionize PPE inspection processes. Digital platforms offer features like real-time data capture, automated scheduling, and instant reporting, which streamline inspections and ensure timely corrective actions. For instance, the Augmented & Connected Worker platform allows for the creation of digital work orders, real-time monitoring, and analytics, facilitating a more efficient and compliant inspection routine. blog.glartek.com

Benefits of Optimized Digital PPE Inspection Checklists

-

Consistency and Compliance : Digital checklists standardize inspection procedures, ensuring that all safety protocols are uniformly followed across various teams and locations. Manifest blog, glartek.com

-

Real-Time Reporting : Immediate data capture and sharing enable swift identification and resolution of potential safety issues, enhancing overall workplace safety. blog.glartek.com

-

Data-Driven Decision Making : Collected data can be analyzed to identify trends, allowing organizations to make informed decisions regarding safety improvements and resource allocation.

Implementing Digital PPE Inspection Solutions

To successfully transition from paper-based to digital PPE inspections, organizations should: blog.glartek.com

-

Assess Current Processes : Evaluate existing inspection methods to identify inefficiencies and areas for improvement.

-

Select Appropriate Digital Tools : Choose a digital inspection platform that aligns with the organization's specific needs and integrates seamlessly with existing systems.

-

Train Employees : Provide comprehensive training to ensure that all personnel are proficient in using the new digital tools and understand the benefits of the transition.

-

Monitor and Refine : Continuously monitor the effectiveness of the digital inspection process and make necessary adjustments to optimize performance.

By adopting digital solutions for daily PPE inspections, organizations can enhance safety compliance, improve operational efficiency, and foster a proactive safety culture. This strategic move not only protects employees but also contributes to the overall productivity and reputation of the company.

Worker Name:

________________________

Date:

_______________________________

Inspector Name:

______________________

1. Hard Hats

☐

No visible cracks, dents, or damage.

☐

Worn properly (bill forward, snug fit).

☐

Chin strap used (if required).

2. Safety Glasses/Goggles

☐

Free from scratches, cracks, or damage.

☐

Worn in designated areas (e.g., cutting, grinding).

☐

Properly fitted (no slipping, covers eyes fully).

3. Gloves

☐

Appropriate type for the task(e.g., cut-resistant, chemical-resistant).

☐

No tears, holes, or excessive wear.

☐

Properly sized for comfort and safety.

4. High-Visibility Vests

☐

Clean and reflective strips intact.

☐

Worn at all times on-site.

☐

Proper fit (not too loose or tight).

5. Steel-Toe Boots

☐

Proper fit and in good condition (no cracks or holes).

☐

Non-slip soles intact.

☐

Laces or straps secured to prevent tripping.

6. Hearing Protection

☐

Earplugs or earmuffs available.

☐

Worn in high-noise areas (e.g., machinery, power tools).

☐

Properly fitted (earplugs inserted correctly, earmuffs snug).

7. Respirators/Masks (if required)

☐

Correct type for the hazard(e.g., dust, fumes).

☐

Proper fit and seal (no gaps).

☐

Filters/cartridges in good condition and not expired.

8. Fall Protection (if required)

☐

Harness and lanyard inspected for damage.

☐

Properly worn and adjusted (straps snug, D-ring centered).

☐

Anchorage point verified and secure.

9. Additional PPE (if required)

☐

Face shields (used with safety glasses, no damage).

☐

Knee pads (properly fitted, no damage).

☐

Coveralls/protective clothing (appropriate for task, no tears).

Inspector Notes:

-

Any issues observed (e.g., damaged PPE, non-compliance):

-

Corrective actions taken:

Worker Signature:

________________________

Inspector Signature:

______________________

Free Download for the PPE check list:

Download PPE Inspection Check List image format

Download PPE Inspection Check List Word format

Download PPE Inspection Check List Excel format

Download PPE Inspection Check List PDF format