Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Templates

Inspecting the hydraulic components of a heavy-duty crane to prevent leaks and failures.

Inspecting the hydraulic components of a heavy-duty crane to prevent leaks and failures.

Why Crane Inspections Are Essential

Regular inspections of cranes and heavy machinery are critical for workplace safety, regulatory compliance, and accident prevention . Equipment failures can lead to serious injuries, costly downtime, and OSHA violations .

This free crane inspection checklist provides a structured, easy-to-follow process to ensure all components of your heavy machinery remain in optimal condition .

Benefits of Using This Checklist:

✔

Ensure OSHA compliance

and reduce workplace risks

✔

Prevent unexpected mechanical failures

✔

Increase the lifespan of heavy machinery

✔

Improve overall safety for operators and workers

Verifying the functionality of crane brakes and emergency stop buttons.

Verifying the functionality of crane brakes and emergency stop buttons.

Download Your Free Weekly Crane Inspection Checklist

This customizable crane inspection checklist is available in Excel, PDF, and Word formats for easy use and modification.

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist PDF

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Excel

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Word

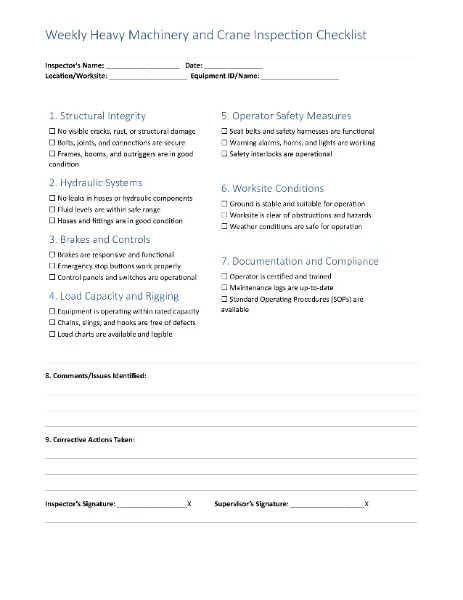

Crane Inspection Checklist Breakdown

1. Structural Integrity

- ☐ No visible cracks, rust, or structural damage

- ☐ Bolts, joints, and connections are secure

- ☐ Frames, booms, and outriggers are in good condition

2. Hydraulic Systems

- ☐ No leaks in hoses or hydraulic components

- ☐ Fluid levels are within the safe range

- ☐ Hoses and fittings are in good condition

3. Brakes and Controls

- ☐ Brakes are responsive and functional

- ☐ Emergency stop buttons work properly

- ☐ Control panels and switches are operational

4. Load Capacity and Rigging

- ☐ Equipment is operating within the rated capacity

- ☐ Chains, slings, and hooks are free of defects

- ☐ Load charts are available and legible

5. Operator Safety Measures

- ☐ Seat belts and safety harnesses are functional

- ☐ Warning alarms, horns, and lights are working

- ☐ Safety interlocks are operational

6. Worksite Conditions

- ☐ Ground is stable and suitable for operation

- ☐ Worksite is clear of obstructions and hazards

- ☐ Weather conditions are safe for operation

7. Documentation and Compliance

- ☐ Operator is certified and trained

- ☐ Maintenance logs are up to date

- ☐ Standard Operating Procedures (SOPs) are available

A worker examining a crane’s metal frame for cracks.

A worker examining a crane’s metal frame for cracks.

Ensure Workplace Safety with This Free Crane Inspection Checklist

Regular inspections enhance safety, minimize downtime, and reduce operational risks . This OSHA-compliant checklist ensures that your heavy machinery and cranes remain in optimal working condition .

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist PDF

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist PDF

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Excel

📥

Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Word

📥 Download Free Customizable Weekly Crane and Heavy Machinery Inspection Checklist Image

References: