Crane Inspection Checklist for Safe Lifting Operations

Ensuring the safety and efficiency of crane operations begins with a thorough inspection of the crane setup, rigging gear, and lift plans. This checklist covers all aspects from equipment examination to safety protocols, providing a comprehensive guide for operators and inspectors. By following these steps, you can minimize risks, ensure compliance with safety regulations, and enhance operational efficiency. With interactive features, users can tick off completed tasks, add comments, and export the checklist for record-keeping and stakeholder communication, all secured with a QR code for authenticity.

- Ensure crane operations are safe and efficient with a comprehensive pre-operation inspection.

- Verify the condition of rigging gear and compliance with safety standards before use.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Systematic inspection helps prevent accidents, ensuring workers' safety and equipment longevity.

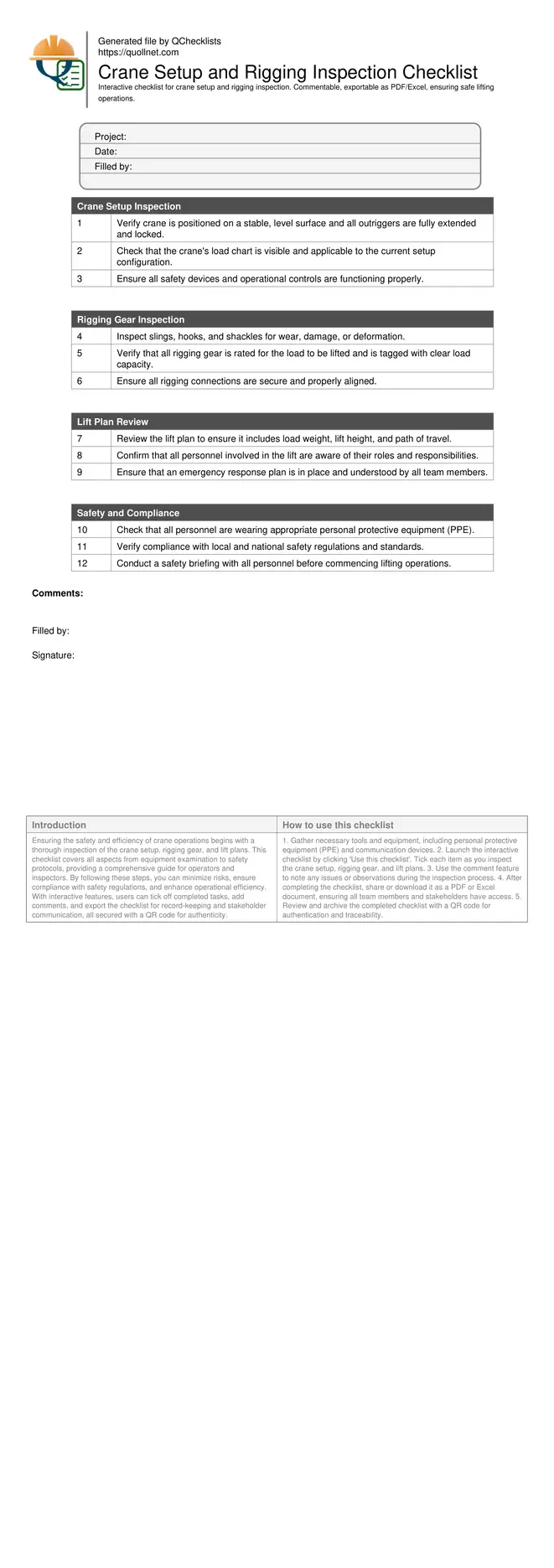

Crane Setup Inspection

Rigging Gear Inspection

Lift Plan Review

Safety and Compliance

Importance of Crane Setup Inspection

Proper crane setup is crucial to safe lifting operations. Inspecting the crane setup involves ensuring the crane is on stable ground, outriggers are fully extended, and load charts are visible and correct. These steps prevent accidents caused by equipment failure or misuse.

- Check for stable, level ground for crane placement.

- Ensure outriggers are fully extended and locked.

- Verify visibility and accuracy of the crane's load chart.

Rigging Gear: Safety First

Rigging gear must be inspected for wear and damage to avoid dangerous lifting failures. Verify that all equipment is rated for the load and properly tagged. Rigging connections should be secure and aligned to maintain load stability.

- Inspect for wear, damage, or deformation.

- Check load capacity ratings and tags.

- Ensure secure and properly aligned connections.

Reviewing the Lift Plan

A comprehensive lift plan outlines the load, lift height, and travel path, ensuring all team members understand their responsibilities. An effective lift plan prevents miscommunication and promotes coordination among the lifting team.

- Include load weight, height, and travel path.

- Assign clear roles and responsibilities.

- Prepare and communicate an emergency response plan.

How to Use This Crane Inspection Checklist

- Gather necessary tools and equipment, including personal protective equipment (PPE) and communication devices.

- Launch the interactive checklist by clicking 'Use this checklist'. Tick each item as you inspect the crane setup, rigging gear, and lift plans.

- Use the comment feature to note any issues or observations during the inspection process.

- After completing the checklist, share or download it as a PDF or Excel document, ensuring all team members and stakeholders have access.

- Review and archive the completed checklist with a QR code for authentication and traceability.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Crane Setup and Rigging Inspection

- Download PDF - Crane Setup and Rigging Inspection

- View Image - Crane Setup and Rigging Inspection