False Ceiling Inspection & Panel Installation Guide

This checklist is designed to guide professionals in the inspection of false ceiling suspension and panel installations. It covers key areas such as structural integrity, alignment, materials, and safety compliance. Proper inspection ensures that the ceiling not only looks aesthetically pleasing but also adheres to safety standards, prolonging its lifespan and minimizing maintenance costs. Whether for new installations or regular maintenance, this checklist provides the necessary steps to perform a thorough evaluation.

- Ensure structural integrity by checking the suspension system and panel alignment.

- Verify material quality to prevent future damage and ensure longevity.

- Identify safety hazards early to prevent accidents and ensure compliance.

- Streamline maintenance by documenting issues and solutions during inspections.

- Enhance aesthetic appeal by ensuring proper panel installation and alignment.

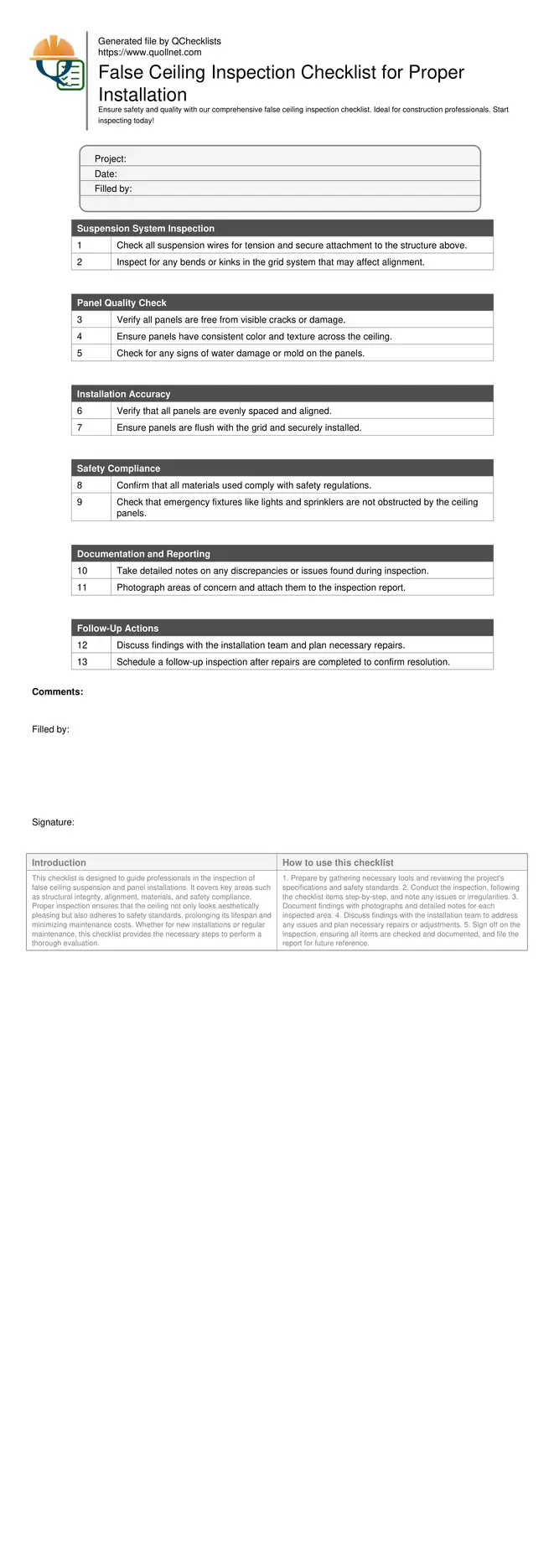

Suspension System Inspection

Panel Quality Check

Installation Accuracy

Safety Compliance

Documentation and Reporting

Follow-Up Actions

Structural Integrity and Safety

Inspecting the structural integrity of a false ceiling is crucial to ensure safety and longevity. Begin by examining the suspension system for signs of wear or damage, as any failure here can lead to the collapse of the ceiling. Ensure that all components are securely fastened and aligned. Regular inspection prevents potential hazards and costly repairs.

- Check for corrosion or damage in suspension components.

- Ensure all fasteners are tight and secure.

- Verify alignment of panels and suspension grid.

- Inspect for any visible sagging or unevenness.

- Confirm compliance with relevant safety standards.

Material Quality and Durability

The quality of materials used in false ceiling installations significantly affects their durability. Inspect each panel for signs of damage such as cracks, warping, or discoloration. High-quality materials reduce maintenance needs and ensure the ceiling withstands environmental stresses over time.

- Examine panels for cracks or other imperfections.

- Check for consistent color and finish on all panels.

- Verify material specifications match project requirements.

- Assess for any signs of moisture damage or mold.

- Ensure protective coatings are intact if applicable.

Installation Accuracy and Aesthetics

Proper installation is key to both the functionality and visual appeal of a false ceiling. Inspect the alignment and spacing of panels to ensure an even and aesthetically pleasing appearance. Proper installation not only enhances visual appeal but also contributes to the overall stability of the ceiling.

- Verify even spacing between panels.

- Check for level installation across the entire ceiling.

- Ensure panels are securely attached to the grid.

- Align panels with lighting and HVAC fixtures.

- Inspect for any visible gaps or misalignments.

How to Use the False Ceiling Inspection Checklist

- Prepare by gathering necessary tools and reviewing the project's specifications and safety standards.

- Conduct the inspection, following the checklist items step-by-step, and note any issues or irregularities.

- Document findings with photographs and detailed notes for each inspected area.

- Discuss findings with the installation team to address any issues and plan necessary repairs or adjustments.

- Sign off on the inspection, ensuring all items are checked and documented, and file the report for future reference.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - False Ceiling Inspection Checklist

- Download PDF - False Ceiling Inspection Checklist

- View Image - False Ceiling Inspection Checklist