Open NCRs at Taking-Over / DLP

Summary

Open Non confromance report - NRC at taking-over are common, but they must be controlled. Taking-over can usually proceed only if the remaining NCRs do not prevent safe use of the works and do not block statutory approvals or system performance. The right practice is to (1) classify NCRs as “blocker” vs “non-blocker,” (2) attach an Outstanding NCR Schedule to the taking-over documentation, (3) apply commercial controls where relevant (withhold/deduction tied to a clear reference), and (4) escalate persistent or ignored NCRs into contractual notices under the authority defined in the contract (Engineer/CA/PM/Employer’s Rep).

1) What “taking-over” means (and why open NCRs matter)

Taking-over (handover) is the contractual milestone where the Employer/Client accepts the Works (or a Section) as complete enough to take possession and use. It typically triggers major consequences such as:

start of the Defects Liability Period (DLP) / defects regime,

changes in risk/possession and operational responsibility,

payment milestones (e.g., release of part retention, final account steps).

Open NCRs matter because they can affect safety, use, approvals, final valuation, and the project’s ability to close out cleanly.

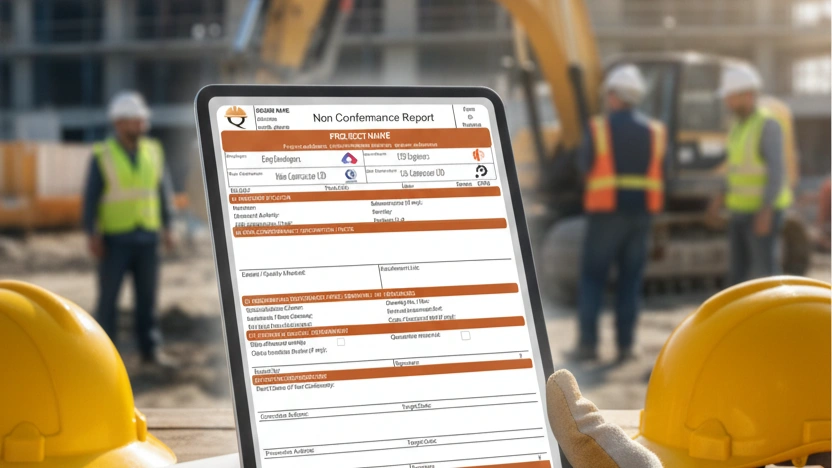

2) Key definitions (keep these separate)

NCR (Non-Conformance Report): a QA/QC record raised when work/material/testing/documentation does not meet contract requirements.

Snag / punch list: typically minor completion/finishing items. Example Snag list

Defect: a nonconforming condition managed under the defects regime (often after taking-over).

Outstanding works: incomplete items remaining at handover.

In practice, many teams treat open NCRs at handover as “outstanding defects/outstanding works”—but you should only do this when the NCR is not a handover blocker.

3) Who has authority at taking-over (common structures)

Different contract families use different titles, but the practical control usually sits with one of:

Engineer / Consultant (FIDIC-style supervision/administration),

Contract Administrator (CA) (JCT-style),

Project Manager / Employer’s Representative (NEC-style PM),

plus Authorities Having Jurisdiction (AHJ) for occupancy/permits (where relevant).

Your project procedures should clearly state:

who can certify taking-over/substantial completion,

who can issue instructions (to correct),

who can issue contractual notices (default/cure/termination steps).

4) The decision rule: can we take over with open NCRs?

A) “Blocker NCRs” (taking-over should not be issued)

Treat an NCR as a blocker when it prevents safe or compliant use, for example:

safety / structural integrity concerns (or unverified critical repairs),

life-safety systems not proven (fire alarm cause & effect, smoke control, etc.),

statutory approvals/permits/commissioning requirements not met,

performance-critical tests incomplete or failed where operation would be unsafe.

B) “Non-blocker NCRs” (taking-over may proceed with controls)

Often acceptable when:

the NCR is minor and correctable post-handover,

a clear corrective action plan exists,

verification method and evidence are defined,

commercial controls are documented where relevant.

Practical principle: Handover can proceed with outstanding items that do not prevent intended use—if they are transparently listed, time-bound, and verifiable.

5) How to document open NCRs at taking-over (best practice)

5.1 Attach an annex: Outstanding NCR Schedule

At taking-over, create an annex listing all open NCRs, including:

NCR ID

location / element

brief nonconformance description (facts)

severity (minor/major/critical)

required action (repair/replace/retest/submittal)

responsible party

target closure date

verification method and evidence required

optional: IPC hold/deduction reference

optional: contractual notice reference/date (if escalated)

This mirrors the common industry practice of issuing a taking-over/substantial completion document with a list of outstanding defects/works attached.

5.2 Keep the NCR Log “light,” but traceable

Your NCR log/register should stay QA-focused and only record high-level commercial/contract admin references (e.g., IPC ref, amount held, notice ref/date). The detailed QS valuation and contractual follow-up should be in separate registers.

6) Commercial impacts at handover (withholding, holds, deductions)

Open NCRs often become commercial at handover through:

withheld valuation (work not certified/measured until compliant),

IPC deductions/holds linked to specific NCRs,

concession/acceptance with a credit (where the contract allows acceptance of a deviation with a value adjustment).

Field example (UAE – supplier/subcontractor compliance)

On Julphar Residence / Al Reem Island (Employer: RAK Properties; A/E: Arkconsult; Contractor: S.E.G. Emirates), a recurring real-world pattern occurred: some work met technical specs and was operational, but sourcing allegedly did not match the approved supplier/subcontractor list. The Engineer/Employer position presented was effectively: remove/replace or accept a deduction, and deductions were applied without clear supporting build-up provided to the contractor.

How to present this professionally in your article (without escalating dispute language):

“Some projects treat approved supplier/subcontractor compliance as a contractual requirement independent of technical performance.”

“Resolution may be replacement, or a concession paired with a commercial adjustment—ideally supported by a transparent valuation reference.”

7) When open NCRs should escalate to contractual notices

An NCR becomes a contractual risk when:

the contractor does not respond within required time,

corrective action is not implemented,

deadlines are repeatedly missed,

the issue is systemic/repeated,

the NCR blocks taking-over or safe use.

7.1 “Notice to Correct” (FIDIC-style example)

In FIDIC 1999-style wording, a Notice to Correct is used when the contractor fails to carry out an obligation, requiring remedy within a specified reasonable time. This is a recognized escalation step before stronger remedies.

7.2 Defects correction periods and completion logic (NEC-style example)

NEC guidance highlights that defects notified before completion have correction periods linked to completion, and that completion can be certified when defects do not prevent use (depending on the contract’s completion definition).

7.3 Substantial completion with outstanding items (AIA-style example)

AIA A201-style provisions commonly tie substantial completion to the Owner’s ability to occupy/use the work, and require correction of items that prevent such use before the certificate is issued.

8) Practical “do this at handover” checklist

Separate NCRs into blocker vs non-blocker.

If blocker: delay taking-over or do sectional/partial taking-over.

If non-blocker: issue taking-over with an Outstanding NCR Schedule annex.

Ensure each open NCR has: target date + verification method + evidence.

Track commercial impacts by reference (IPC ref/amount), not by re-doing QS valuation in QA logs.

If contractor ignores NCRs: escalate to the contract admin route (notice reference + date + cure timeline in the contract notices log).

References and Downlaods

GIZ – Taking-Over Certificate template (includes “List of defects/outstanding works” enclosure)

FIDIC – “Restraints on the Execution of Works” (quotes FIDIC 1999 Sub-Clause 15.1 Notice to Correct)International Construction Knowledge Hub – FIDIC 1999 Commentary on Clause 15 (Notice to Correct overview)NEC – Defining and managing defects in ECC (defect correction period timing)Sharpe Pritchard – Defects under NEC4 (completion/defects summary incl. defect correction period)