Collapsed As-Built (But-For) Analysis in Construction Projects

Introduction

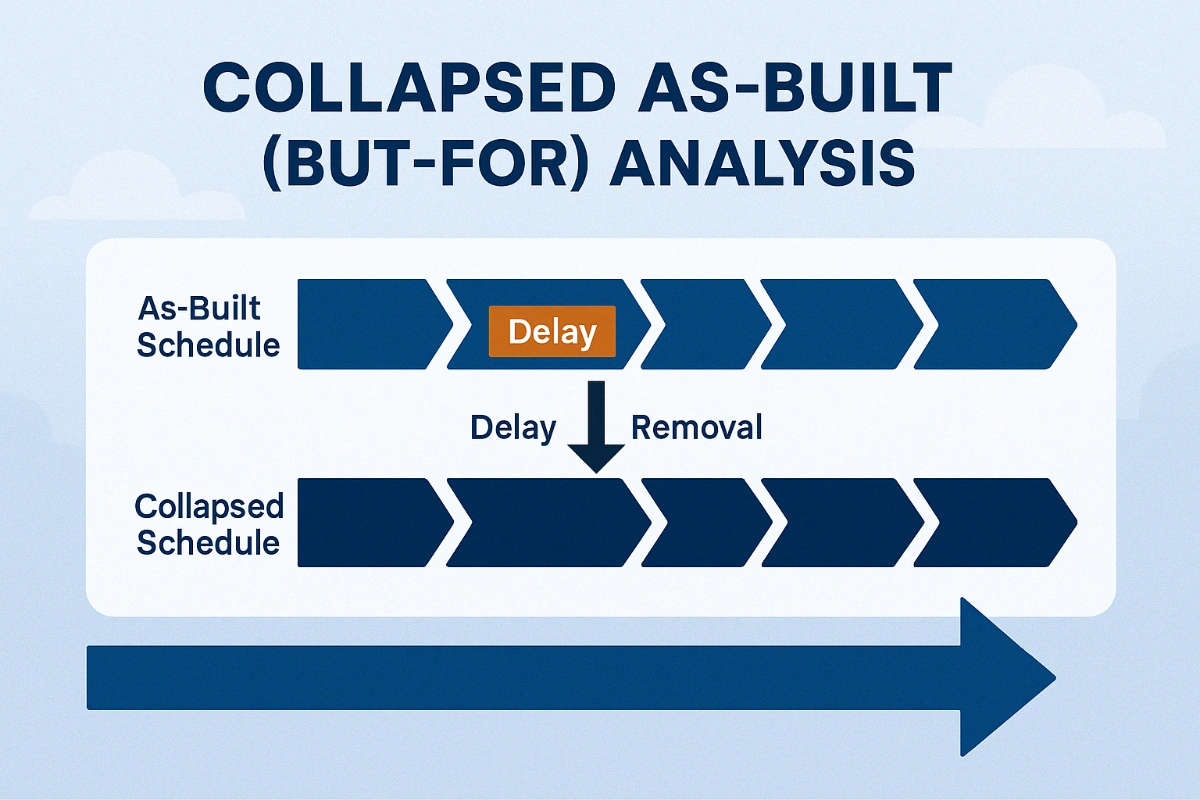

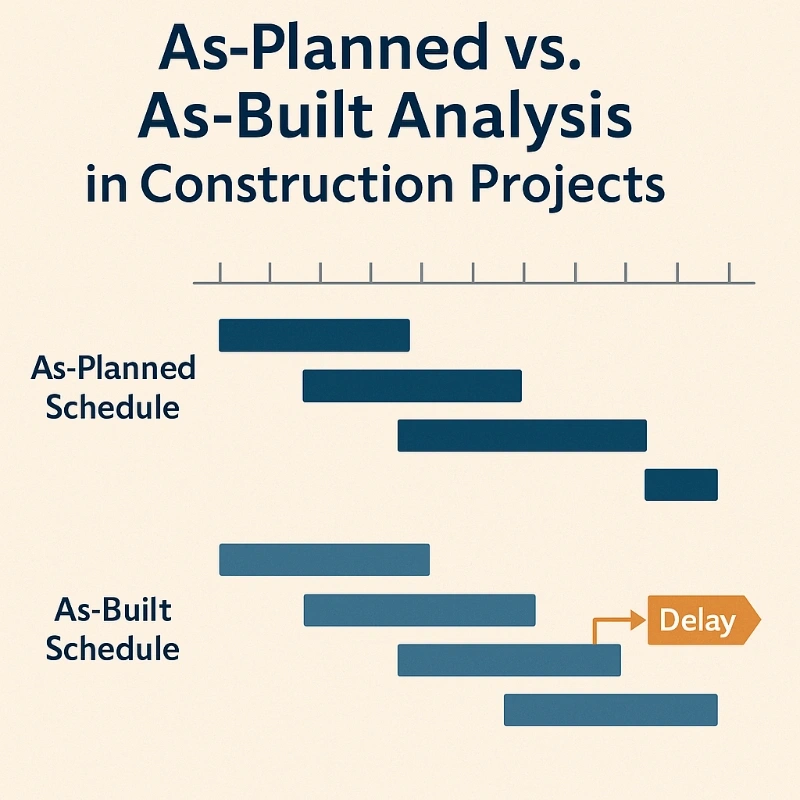

Collapsed As-Built, often referred to as But-For Analysis, is a retrospective delay analysis method used to assess how a project would have progressed but for specific delay events. By removing delays from the actual as-built schedule, this method models a hypothetical scenario to determine whether the delay truly impacted the project’s completion date.

It is widely used in formal claims, arbitration, and forensic delay assessments, especially when a detailed as-built schedule and robust records are available.

1. What Is Collapsed As-Built Analysis?

In this method, analysts take the final as-built schedule and remove one or more delay events (typically owner-related or excusable delays). The goal is to simulate what the finish date would have been if those delays hadn't occurred.

This "collapsed" schedule shows the adjusted project timeline, offering a basis to measure actual vs. theoretical impact.

2. How the Analysis Works

Step 1:

Start with the completed as-built schedule, including all activities and actual dates.

Step 2:

Identify and remove delay-related activities (e.g., design approval hold, variation order) from the schedule.

Step 3:

Recalculate the schedule using Critical Path Method (CPM) tools (e.g., Primavera P6, MS Project).

Step 4:

Compare the recalculated finish date with the actual finish date to determine delay impact.

3. Mini Case Example

A project finishes on Day 320. Analysts remove three owner-driven delay events totaling 30 days.

The revised schedule shows a finish on Day 280.

Delay attributable to owner = 320 - 280 = 40 days.

This outcome supports a potential Extension of Time (EOT) or claim for excusable delay.

4. When to Use This Method

-

After project completion

-

When comprehensive as-built data is available

-

In forensic dispute analysis or arbitration

-

To evaluate entitlement in complex delay scenarios

5. Pros and Cons

| Aspect | Pros | Cons |

|---|---|---|

| Precision | Based on actual execution | Relies on accurate as-built data |

| Legal Weight | Common in court/arbitration | May be challenged as hypothetical |

| Transparency | Clearly isolates impact of selected delays | Doesn’t reflect mitigation or concurrent delays unless modeled separately |

6. Contractual & Legal Context

Collapsed As-Built is widely accepted in formal disputes when supported by:

-

Auditable as-built schedules

-

Daily logs and correspondence

-

Industry protocols like AACEI RP 29R-03 or SCL Protocol

However, it is often scrutinized for:

-

Over-simplification of real project dynamics

-

Omission of float consumption or acceleration efforts

-

Potential for bias if key delays are selectively removed

7. Best Practices

-

Document all delay events and mitigation efforts contemporaneously.

-

Maintain detailed as-built schedules and daily progress records.

-

Use CPM tools with full logic tie visibility.

-

Remove delays incrementally to measure individual impacts.

-

Validate findings with contractual clauses (e.g., FIDIC 8.4, NEC time risk allowances).

8. Support Your Delay Claims with Expert Tools

Use the Collapsed As-Built method more effectively with these free, professional tools designed for retrospective delay analysis and claim preparation:

-

✅ Construction Delay Log Template – Document all delay events linked to specific activities.

-

✅ Daily Site Delay Report Sample – Capture evidence for as-built validation.

-

✅ EOT Claim Submission Checklist – Make sure your delay claims meet all contractual and procedural requirements.

Conclusion

Collapsed As-Built analysis offers a powerful tool to test the what-if scenario of delay removal in completed projects. It is especially useful in arbitration or litigation settings where clarity on causation is critical. However, the accuracy and fairness of this method depend entirely on the integrity of the as-built data and transparency in fragnet removal. When used responsibly, it can be a compelling method to support or defend delay-related claims.