As-Planned vs. As-Built Analysis in Construction Projects

Introduction

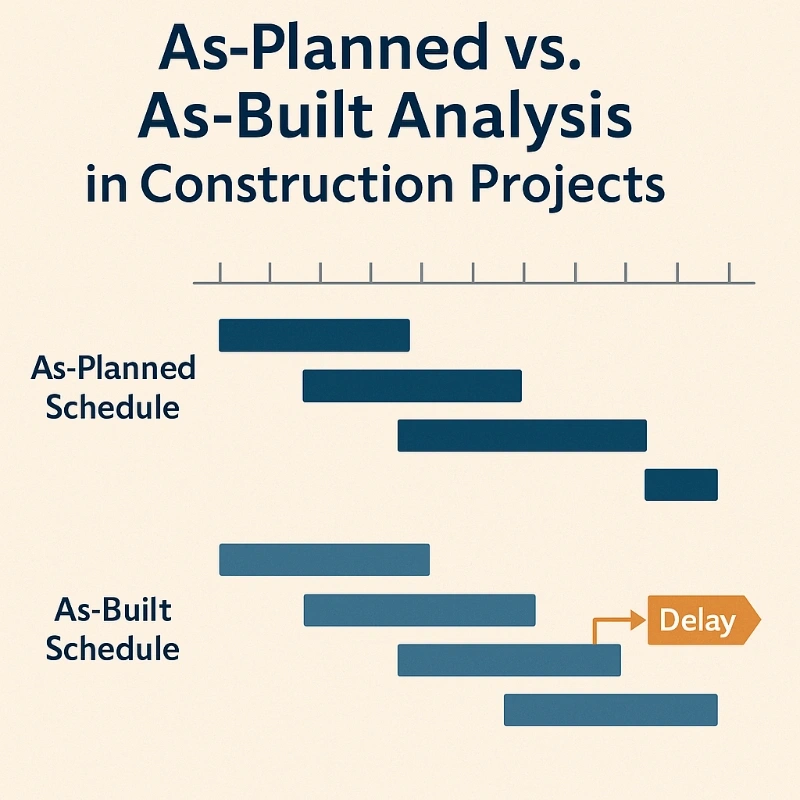

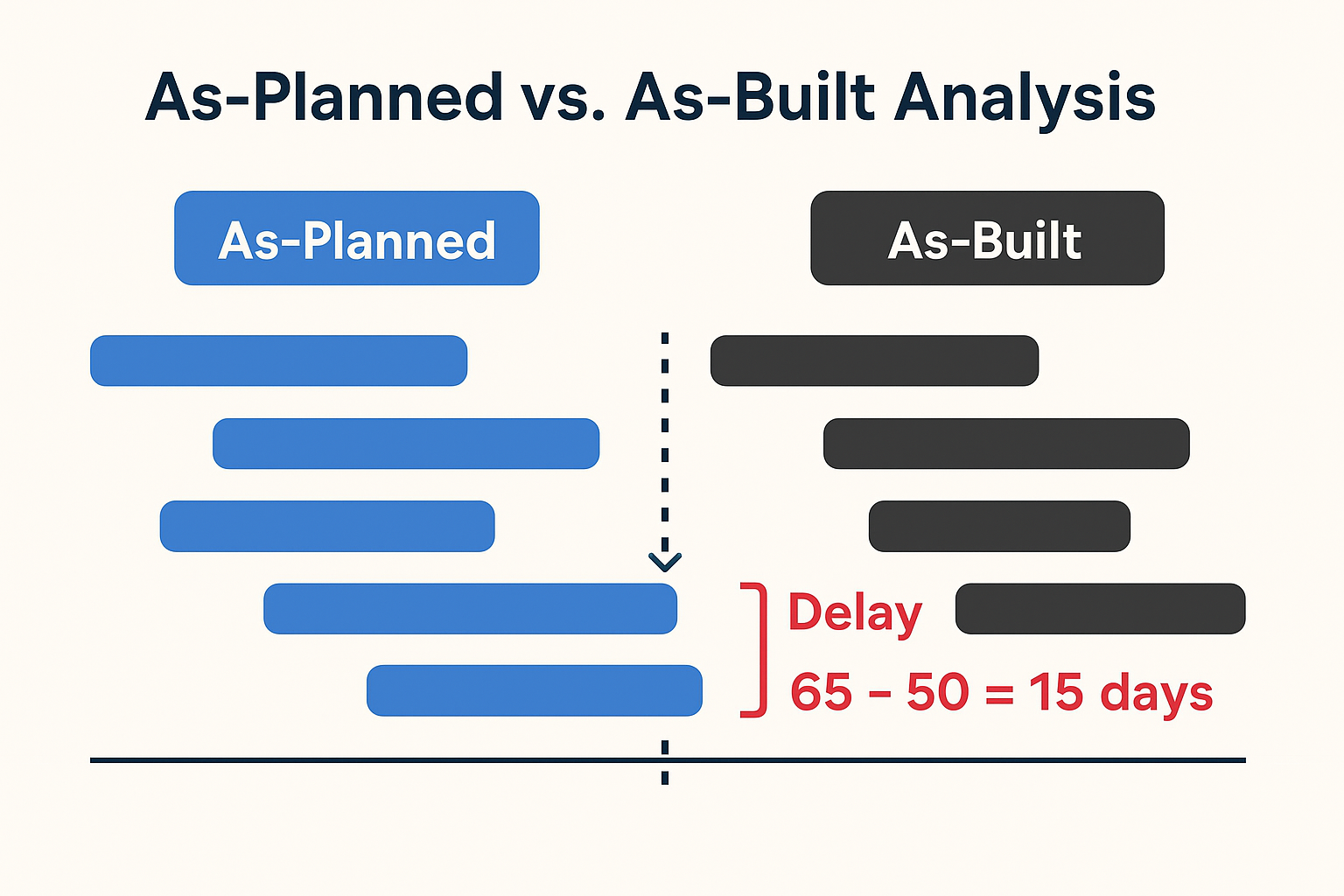

As-Planned vs. As-Built analysis is one of the most commonly used retrospective methods for assessing construction delays. It compares what was originally scheduled (the as-planned program) to what actually happened (the as-built timeline) to determine the extent and cause of delays. It is widely accepted in post-project delay claims and disputes.

1. What Is As-Planned vs. As-Built?

This method involves overlaying the original construction schedule with actual progress records. Delays are identified by analyzing variances between planned and actual task start and finish dates. This approach helps determine whether delays were:

-

Caused by the contractor

-

Due to client-side issues

-

Unforeseen external factors

It’s best used after project completion or when sufficient actual data is available.

2. How the Analysis Works

-

Step 1: Collect the baseline (as-planned) schedule and progress updates.

-

Step 2: Build or extract the as-built schedule using site records, daily reports, and updates.

-

Step 3: Compare activity-by-activity to highlight deviations.

-

Step 4: Identify impacts on the project’s critical path and completion date.

3. Example Application

If the as-planned schedule shows “Steel Delivery” on Day 45 but the as-built record shows it occurred on Day 70, the delay is 25 days. By checking if this task was on the critical path, the analyst can determine whether this delay impacted the overall project delivery.

4. Contractual Relevance

Contracts such as FIDIC, NEC, and JCT accept this method for evaluating claims after delays have occurred, especially when prospective methods like TIA are no longer suitable.

However, its reliability depends on:

-

A valid baseline schedule

-

Accurate and detailed as-built records

5. Pros and Cons

| Aspect | Pros | Cons |

|---|---|---|

| Timing | Good for completed or nearly-complete projects | Not useful for live project forecasting |

| Simplicity | Clear comparison of scheduled vs. actual | May oversimplify complex concurrent delays |

| Acceptance | Common in arbitration | Can be challenged if records are inconsistent |

6. Common Challenges

-

Inconsistent or missing progress updates

-

Manipulation of as-built data to influence outcome

-

Overlooking logical sequencing and float consumption

-

Not accounting for weather or force majeure impacts

7. Best Practices

-

Maintain detailed daily logs, schedules, and updates throughout the project.

-

Use software like Primavera P6 or MS Project with audit trails.

-

Pair this method with delay event logs and change order records for better accuracy.

8. Tools to Support Your Delay Analysis

Accurate As-Planned vs. As-Built analysis starts with structured documentation and clarity. To streamline your delay evaluation and EOT claims, download these free, ready-to-use tools:

-

✅ Construction Delay Log Template – Track delay events with EOT IDs and impacts.

-

✅ Daily Site Delay Report Sample – Standardized report for day-by-day delay documentation.

-

✅ EOT Claim Checklist – Ensure every delay claim you submit is contractually compliant and fully supported.

✅ Construction Delay Log Template – Track delay events with EOT IDs and impacts.

✅ Daily Site Delay Report Sample – Standardized report for day-by-day delay documentation.

✅ EOT Claim Checklist – Ensure every delay claim you submit is contractually compliant and fully supported.

Conclusion

As-Planned vs. As-Built is a foundational technique for understanding construction delays after the fact. When supported by reliable data and used with critical path analysis, it provides a clear view of what went wrong, when, and why—making it valuable in both claims preparation and forensic delay analysis.