Lifting Anchors and Embedded Plates Inspection Guide

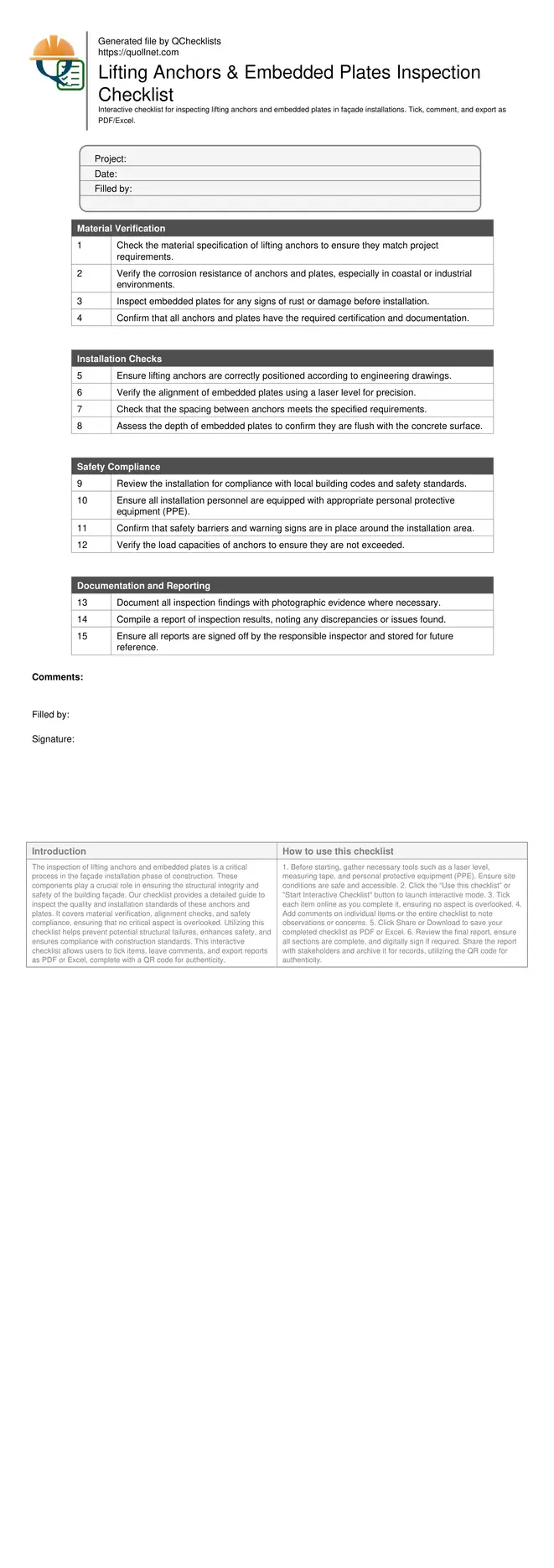

The inspection of lifting anchors and embedded plates is a critical process in the façade installation phase of construction. These components play a crucial role in ensuring the structural integrity and safety of the building façade. Our checklist provides a detailed guide to inspect the quality and installation standards of these anchors and plates. It covers material verification, alignment checks, and safety compliance, ensuring that no critical aspect is overlooked. Utilizing this checklist helps prevent potential structural failures, enhances safety, and ensures compliance with construction standards. This interactive checklist allows users to tick items, leave comments, and export reports as PDF or Excel, complete with a QR code for authenticity.

- Ensure the structural integrity and safety of façade installations through thorough inspections.

- Prevent potential structural failures by verifying quality and installation standards.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Facilitate compliance with construction standards for anchors and plates.

Material Verification

Installation Checks

Safety Compliance

Documentation and Reporting

Importance of Material Verification

Material verification is a foundational step in ensuring that lifting anchors and embedded plates meet the necessary quality standards for façade installations. It involves checking the material specifications, corrosion resistance, and physical condition of the components. These checks are crucial, especially in environments prone to corrosion or where high structural loads are expected.

- Ensures materials meet project specifications.

- Prevents premature failure due to corrosion.

- Confirms the presence of necessary certifications.

- Identifies potential defects before installation.

Ensuring Proper Installation

Proper installation of lifting anchors and embedded plates is vital for the stability and safety of the façade. This involves precise positioning, alignment, and spacing checks to ensure the components function as intended. Inadequate installation can lead to structural failures, posing significant safety risks.

- Aligns with engineering drawings for accuracy.

- Ensures precise spacing and alignment.

- Verifies depth and flush installation with surfaces.

- Prevents installation-related structural issues.

Adhering to Safety Compliance

Safety compliance is non-negotiable in construction. This involves ensuring that all installation activities adhere to local building codes and safety standards, and that personnel are equipped with the necessary protective gear. Safety measures mitigate risks associated with the installation process.

- Prevents safety hazards on-site.

- Ensures compliance with local regulations.

- Protects personnel with appropriate PPE.

- Secures the worksite with barriers and signs.

How to Use the Lifting Anchors and Plates Inspection Checklist

- Before starting, gather necessary tools such as a laser level, measuring tape, and personal protective equipment (PPE). Ensure site conditions are safe and accessible.

- Click the “Use this checklist” or "Start Interactive Checklist" button to launch interactive mode.

- Tick each item online as you complete it, ensuring no aspect is overlooked.

- Add comments on individual items or the entire checklist to note observations or concerns.

- Click Share or Download to save your completed checklist as PDF or Excel.

- Review the final report, ensure all sections are complete, and digitally sign if required. Share the report with stakeholders and archive it for records, utilizing the QR code for authenticity.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Inspection of Lifting Anchors and Embedded Plates

- Download PDF - Inspection of Lifting Anchors and Embedded Plates

- View Image - Inspection of Lifting Anchors and Embedded Plates

Cite & Embed

“Inspection of Lifting Anchors and Embedded Plates by Quollnet”

with a link to

this source page.