Inspecting Pavement Expansion Joints and Sealants

Inspecting expansion joints and sealant for pavements is crucial for maintaining the integrity and longevity of paved surfaces. This process involves assessing the joints that accommodate thermal expansion and contraction, as well as the sealants that protect these joints from moisture and debris. Proper inspection can prevent costly repairs, ensure safety, and extend the lifespan of pavements. This checklist guides you through the essential steps for a thorough inspection, from preparatory work to final documentation. Use our interactive features to tick off tasks, leave comments, and generate comprehensive reports with unique QR codes for authenticity.

- Ensure pavement durability by regularly inspecting expansion joints and sealants.

- Prevent moisture and debris infiltration by maintaining effective sealants.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Reduce maintenance costs by identifying issues early through systematic inspections.

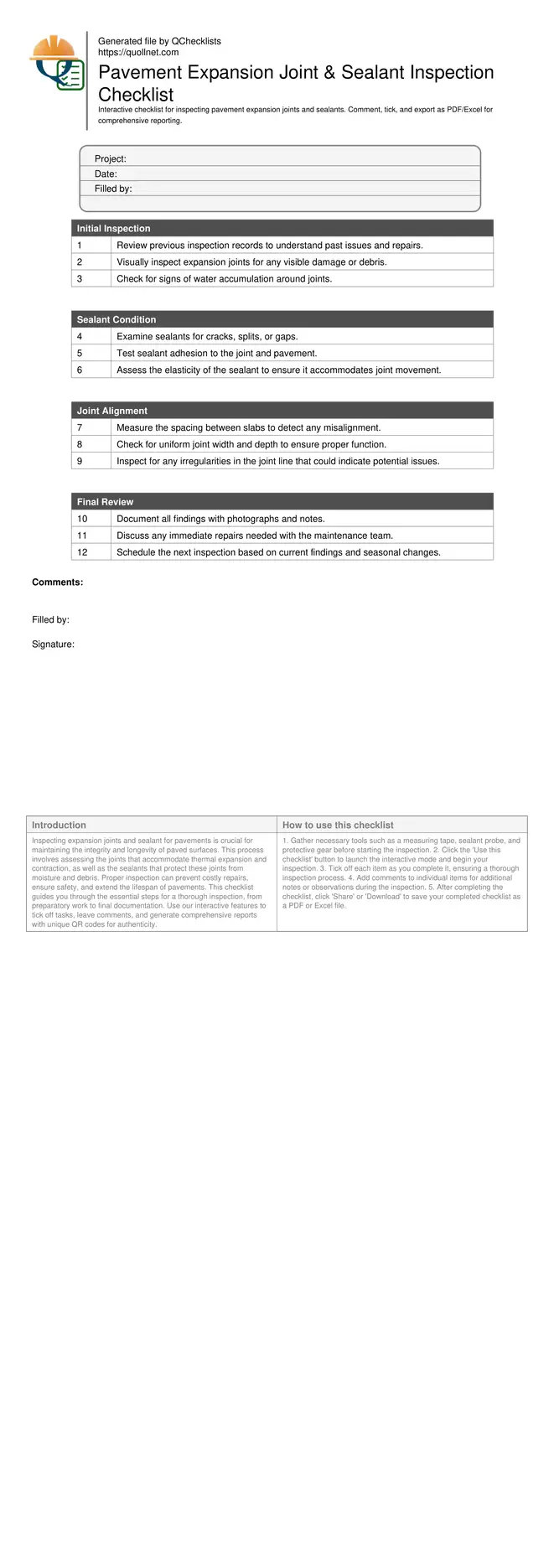

Initial Inspection

Sealant Condition

Joint Alignment

Final Review

Understanding Expansion Joints

Expansion joints are crucial components in pavements that allow for the thermal movement of slabs. These joints prevent cracking and buckling by providing space for the slabs to expand and contract. Regular inspection of these joints is necessary to ensure that they are functioning correctly and are not compromised by external factors.

- Identify signs of wear or damage in joint materials.

- Check for debris accumulation that can impede joint function.

- Assess the alignment and spacing between slabs.

- Ensure that joints are free from standing water.

Sealant Inspection Techniques

Sealants play a vital role in protecting expansion joints from moisture and debris. Over time, sealants can degrade, losing their protective properties. Inspecting sealants involves checking for cracks, adhesion failure, and other signs of wear that could compromise pavement integrity.

- Look for cracks or gaps in the sealant.

- Test for proper adhesion to the pavement surface.

- Ensure sealant elasticity to accommodate joint movement.

- Evaluate UV resistance and weathering of the sealant.

Common Issues and Solutions

During inspections, several common issues may arise, including joint misalignment and sealant degradation. Understanding these issues and implementing corrective measures promptly can mitigate extensive damage and prolong pavement life.

- Address any joint misalignment to prevent structural stress.

- Replace degraded sealants to restore protection.

- Implement a routine maintenance schedule for early problem detection.

- Use high-quality materials to extend the life of joints and sealants.

How to Use This Pavement Inspection Checklist

- Gather necessary tools such as a measuring tape, sealant probe, and protective gear before starting the inspection.

- Click the 'Use this checklist' button to launch the interactive mode and begin your inspection.

- Tick off each item as you complete it, ensuring a thorough inspection process.

- Add comments to individual items for additional notes or observations during the inspection.

- After completing the checklist, click 'Share' or 'Download' to save your completed checklist as a PDF or Excel file.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Pavement Expansion Joint and Sealant Inspection

- Download PDF - Pavement Expansion Joint and Sealant Inspection

- View Image - Pavement Expansion Joint and Sealant Inspection