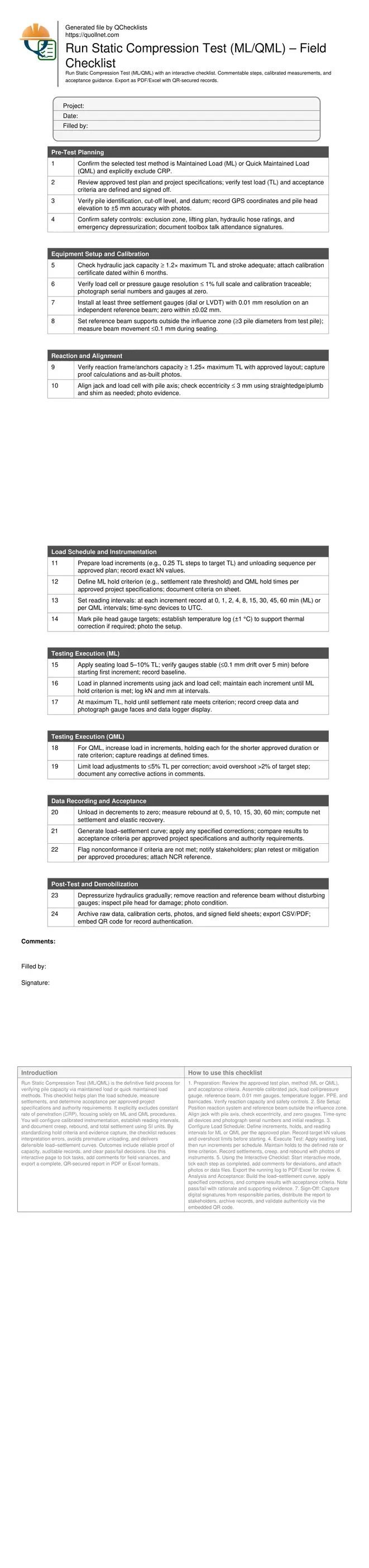

Run Static Compression Test (ML/QML) Checklist

Definition: Run Static Compression Test (ML/QML) for pile foundations, guiding field engineers through load scheduling, settlement measurements, acceptance decisions, and documentation while explicitly excluding constant rate of penetration (CRP) procedures.

- Define ML or QML method, exclude CRP, align with approved plan.

- Set load increments, hold times, and settlement reading intervals.

- Capture calibrated readings, photos, signatures, and traceable data exports.

- Interactive, commentable checklist with export and QR code verification.

Run Static Compression Test (ML/QML) is the definitive field process for verifying pile capacity via maintained load or quick maintained load methods. This checklist helps plan the load schedule, measure settlements, and determine acceptance per approved project specifications and authority requirements. It explicitly excludes constant rate of penetration (CRP), focusing solely on ML and QML procedures. You will configure calibrated instrumentation, establish reading intervals, and document creep, rebound, and total settlement using SI units. By standardizing hold criteria and evidence capture, the checklist reduces interpretation errors, avoids premature unloading, and delivers defensible load–settlement curves. Outcomes include reliable proof of capacity, auditable records, and clear pass/fail decisions. Use this interactive page to tick tasks, add comments for field variances, and export a complete, QR-secured report in PDF or Excel formats.

- This checklist standardizes ML and QML static compression testing for piles, from method confirmation and load scheduling to settlement measurement, data interpretation, and acceptance aligned with approved project specifications and authority requirements.

- Technicians get precise instructions for instrumentation setup, calibrated load application, reading intervals, and creep/rebound capture. Evidence requirements ensure traceability, including photos of gauges, data exports, and signatures with time-synchronized records.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Clear acceptance guidance compares measured settlements and creep rates against the approved criteria, helping teams avoid misinterpretation, minimize retests, and deliver reliable capacity assessments suitable for design validation and compliance.

Pre-Test Planning

Equipment Setup and Calibration

Reaction and Alignment

Load Schedule and Instrumentation

Testing Execution (ML)

Testing Execution (QML)

Data Recording and Acceptance

Post-Test and Demobilization

Purpose, Scope, and Method Selection

Static compression testing verifies pile capacity and load–settlement response under controlled, measured loading. This checklist covers Maintained Load (ML) and Quick Maintained Load (QML) methods only; constant rate of penetration (CRP) is excluded. Use it to plan the load schedule, define hold criteria, and structure settlement measurements in SI units. Selecting ML or QML should reflect geotechnical objectives, schedule, and specification requirements. ML emphasizes time-dependent behavior via longer holds, while QML prioritizes efficiency with shorter stabilization periods. Clear documentation—the approved plan, calibration certificates, and time-synchronized readings—protects data integrity and reduces disputes. Safety controls and reaction design prevent instability and accidental releases. By tightening method selection, evidence capture, and acceptance referencing, you avoid premature unloading, misread gauges, and incomplete creep or rebound data. The result is a defensible curve and a clear pass/fail decision for design validation and compliance.

- Use ML for detailed creep and rebound behavior.

- Use QML for efficient, compliant verification.

- Exclude CRP; do not apply constant penetration rate.

- Synchronize time sources across all instruments.

- Ground decisions in the approved test plan.

Instrumentation, Load Scheduling, and Readings

Accurate settlements depend on stable references and calibrated sensors. Install at least three displacement gauges on an independent reference beam positioned outside the influence zone. Verify jack, load cell, and gauges with current certificates and record serials. Define load increments and holds in the plan, including reading intervals that align with ML or QML methodology. Control overshoot and adjust pressure in small steps to hit target loads. Record baseline readings after seating load, then capture settlements and creep during each stage. At peak load, maintain the hold until the specified rate threshold is met; upon unloading, document rebound at defined times. Photos of gauge faces and data-logger screens support traceability. Temperature logs and beam movement checks help interpret anomalies and filter noise from true settlement response.

- Place reference beam beyond three diameters.

- Gauge resolution 0.01 mm or better.

- Control load overshoot within 2% of target.

- Record creep and rebound explicitly.

- Photograph instruments at each key step.

Acceptance, Reporting, and Evidence Control

Acceptance hinges on comparing the measured load–settlement behavior against the approved project specifications and authority requirements. Generate the curve, compute net settlements, and apply any specified corrections, such as elastic shortening adjustments. Review creep rates, maximum settlements at target load, and recovery on unloading. If the pile passes, compile a signed report with calibrated instrument evidence, time-stamped readings, photos, and data exports. If it fails, issue a nonconformance, notify stakeholders, and plan remedial action or a retest. Use the interactive checklist to add clarifying comments, link calculations, and ensure all deliverables are archived with a QR-verified record. Consistency and completeness reduce disputes and accelerate approvals.

- Compare against approved acceptance criteria.

- Attach certificates, photos, and raw exports.

- Document any deviations with comments.

- Secure signatures and approval routing.

- Archive with QR authentication link.

How to Use This ML/QML Static Compression Test Checklist

- Preparation: Review the approved test plan, method (ML or QML), and acceptance criteria. Assemble calibrated jack, load cell/pressure gauge, reference beam, 0.01 mm gauges, temperature logger, PPE, and barricades. Verify reaction capacity and safety controls.

- Site Setup: Position reaction system and reference beam outside the influence zone. Align jack with pile axis, check eccentricity, and zero gauges. Time-sync all devices and photograph serial numbers and initial readings.

- Configure Load Schedule: Define increments, holds, and reading intervals for ML or QML per the approved plan. Record target kN values and overshoot limits before starting.

- Execute Test: Apply seating load, then run increments per schedule. Maintain holds to the defined rate or time criterion. Record settlements, creep, and rebound with photos of instruments.

- Using the Interactive Checklist: Start interactive mode, tick each step as completed, add comments for deviations, and attach photos or data files. Export the running log to PDF/Excel for review.

- Analysis and Acceptance: Build the load–settlement curve, apply specified corrections, and compare results with acceptance criteria. Note pass/fail with rationale and supporting evidence.

- Sign-Off: Capture digital signatures from responsible parties, distribute the report to stakeholders, archive records, and validate authenticity via the embedded QR code.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Static Compression Test (ML/QML) Field Checklist

- Download PDF - Static Compression Test (ML/QML) Field Checklist

- View Image - Static Compression Test (ML/QML) Field Checklist

Cite & Embed

“Static Compression Test (ML/QML) Field Checklist by Quollnet”

with a link to

this source page.