Sealant Backer Rod and Joint Filler Inspection

Inspecting sealant backer rods and joint fillers is crucial for ensuring the durability and effectiveness of expansion joints. These materials, used to fill gaps in construction joints, provide a flexible buffer that absorbs structural movement. A thorough inspection checks for proper installation, ensuring that the materials meet specifications and perform effectively. This inspection covers aspects like material selection, placement, and adherence to guidelines, helping to prevent water ingress and structural damage. Our interactive checklist allows users to tick off items, leave comments, and export reports as PDF or Excel secured by a QR code.

- Ensure sealant backer rods and joint fillers are installed correctly to prevent structural damage and water ingress.

- Thorough inspection helps maintain the longevity and effectiveness of expansion joints.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Quality assurance through detailed inspection of materials, placement, and adherence to specifications.

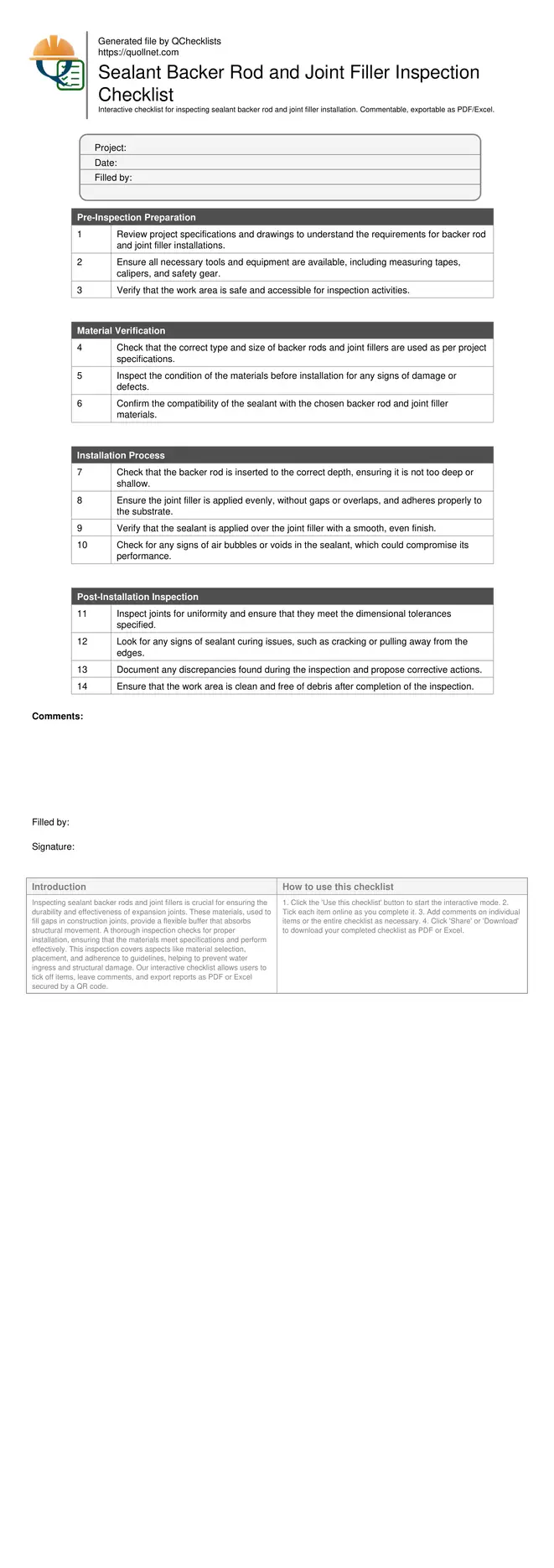

Pre-Inspection Preparation

Material Verification

Installation Process

Post-Installation Inspection

Importance of Proper Installation

Correct installation of sealant backer rods and joint fillers is vital to the integrity of expansion joints. Improper installation can lead to water ingress, structural damage, and increased maintenance costs. This checklist helps ensure that all components are correctly installed and performing as intended, safeguarding the structure's longevity and functionality.

- Prevents potential water ingress.

- Ensures structural integrity.

- Reduces maintenance costs.

- Enhances joint performance.

Common Installation Mistakes

Even skilled professionals can occasionally overlook key aspects of backer rod and joint filler installation. Common mistakes include using incorrect materials, improper depth of installation, and inadequate sealant application. This checklist helps identify and rectify such errors, ensuring a high-quality installation.

- Incorrect material selection.

- Improper installation depth.

- Inadequate sealant application.

- Lack of adherence to guidelines.

How to Use This Checklist

- Click the 'Use this checklist' button to start the interactive mode.

- Tick each item online as you complete it.

- Add comments on individual items or the entire checklist as necessary.

- Click 'Share' or 'Download' to download your completed checklist as PDF or Excel.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Sealant Backer Rod and Joint Filler Inspection

- Download PDF - Sealant Backer Rod and Joint Filler Inspection

- View Image - Sealant Backer Rod and Joint Filler Inspection