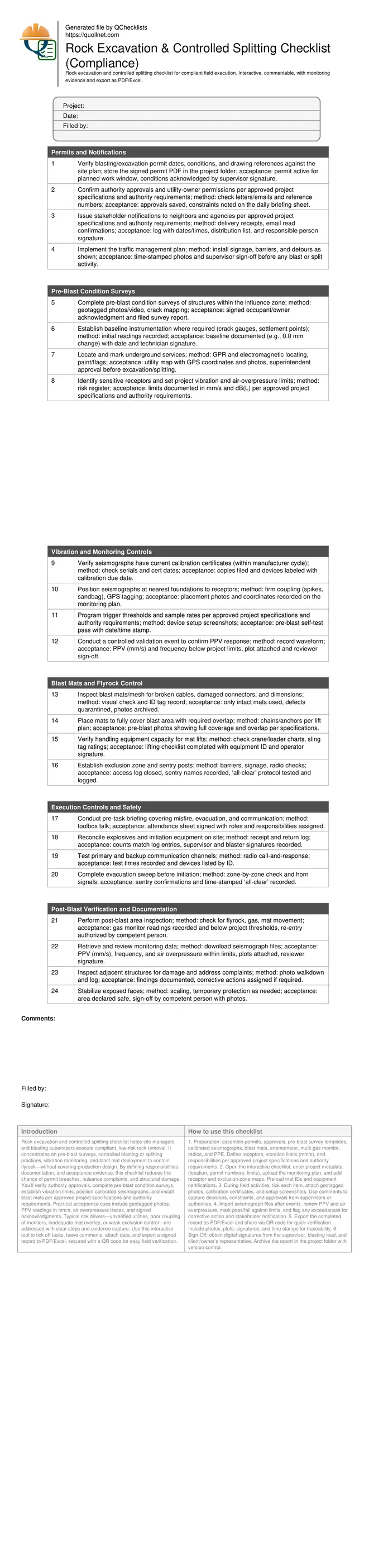

Rock Excavation & Controlled Splitting Checklist

Definition: Rock excavation and controlled splitting checklist for contractors and blasting supervisors, focusing on permits, pre-blast condition surveys, vibration monitoring limits, blast mats, and documentation—explicitly excluding production blast design activities.

- Verify permits, notifications, and pre-blast surveys with dated evidence.

- Set site-specific vibration limits and deploy calibrated seismographs.

- Install blast mats to control flyrock and protect adjacent assets.

- Interactive, commentable, export options with QR code for authentication.

Rock excavation and controlled splitting checklist helps site managers and blasting supervisors execute compliant, low-risk rock removal. It concentrates on pre-blast surveys, controlled blasting or splitting practices, vibration monitoring, and blast mat deployment to contain flyrock—without covering production design. By defining responsibilities, documentation, and acceptance evidence, this checklist reduces the chance of permit breaches, nuisance complaints, and structural damage. You’ll verify authority approvals, complete pre-blast condition surveys, establish vibration limits, position calibrated seismographs, and install blast mats per approved project specifications and authority requirements. Practical acceptance cues include geotagged photos, PPV readings in mm/s, air overpressure traces, and signed acknowledgments. Typical risk drivers—unverified utilities, poor coupling of monitors, inadequate mat overlap, or weak exclusion control—are addressed with clear steps and evidence capture. Use this interactive tool to tick off tasks, leave comments, attach data, and export a signed record to PDF/Excel, secured with a QR code for easy field verification.

- A focused field procedure for rock excavation or controlled splitting that verifies permits, completes pre-blast condition surveys, sets vibration limits, and installs blast mats to control flyrock. It excludes production blast design and centers on documentation, monitoring, and defensible acceptance evidence.

- Practical steps reduce complaints and damage risk: locate and protect utilities, survey adjacent structures, position calibrated seismographs at sensitive receptors, and maintain controlled access and evacuation checks. Acceptance cues include geotagged photos, signed forms, PPV graphs, and inspection records aligned with project requirements.

- Interactive online checklist with tick, comment, and export features secured by QR code. Capture photos, upload seismograph files, log approvals, and generate a time-stamped PDF/Excel report for stakeholders, creating a traceable record of compliance and jobsite decisions.

Permits and Notifications

Pre-Blast Condition Surveys

Vibration and Monitoring Controls

Blast Mats and Flyrock Control

Execution Controls and Safety

Post-Blast Verification and Documentation

Permits, Notifications, and Pre-Blast Surveys

Successful rock excavation or controlled splitting begins with complete administrative control. Confirm blasting or excavation permits, traffic approvals, and utility permissions align with the current drawing set and scheduled windows. Notify neighbors and authorities per approved project specifications and authority requirements, documenting delivery times and recipients. Pre-blast condition surveys of receptors (buildings, utilities, pavements) create a defensible baseline using geotagged photos, annotated crack maps, and occupant acknowledgments. Install baseline tell-tales where required and log initial readings. Define the influence zone and identify sensitive receptors, then set vibration and air-overpressure limits proportionate to receptor fragility and tolerance. This checklist purposely excludes production design, such as charge calculations or hole patterns, and concentrates instead on evidence-backed controls. Clear documentation avoids disputes and accelerates sign-offs, while time-stamped photos and signatures connect field actions with approvals. Tie each permission or survey to a file reference so your team can retrieve proof instantly during inspections or stakeholder reviews.

- File permits and approvals with traceable reference numbers.

- Deliver notifications and record receipts and timestamps.

- Survey receptors with geotagged photos and signed acknowledgments.

- Define influence zone and sensitive receptors early.

- Exclude production blast design from field checklists.

Vibration Limits and Monitoring Execution

Vibration control is a performance risk you can manage with correct limits, placement, and calibration. Establish project-specific peak particle velocity (PPV) limits in mm/s and acceptable frequency ranges per approved project specifications and authority requirements. Use triaxial seismographs with current calibration certificates, logging serial numbers and due dates. Place monitors at the nearest foundations or on-grade locations to receptors, ensuring firm coupling with spikes or sandbags to prevent spurious readings. Program trigger thresholds and sampling per manufacturer guidance, and run a self-test with a screenshot before any blast or split. A controlled validation event confirms the system captures PPV and air overpressure accurately; save plots and compare to limits. During operations, maintain radio contact with the monitoring technician and record exact event times to synchronize data. Afterward, review PPV, frequency, and air overpressure against limits, sign the report, and store files for audit.

- Document PPV limits in mm/s with rationale.

- Place monitors at closest receptor foundations.

- Verify calibration certificates and serial numbers.

- Capture setup screenshots and self-test results.

- Save plots; compare readings to project limits.

Blast Mats, Exclusion, and Post-Event Checks

Blast mats and disciplined exclusion controls minimize flyrock risk and protect adjacent assets. Inspect mats for broken cables, worn connectors, and dimension labels, quarantining any damaged units. Position mats to cover the entire blast area with specified overlap; secure using chains or anchors according to a lift plan. Verify handling equipment capacities and sling tag ratings before moving mats. Establish exclusion zones with barriers, signage, and trained sentries; log radio checks and all-clear signals. Check weather with an anemometer—wind influences dust and mat stability—and prepare water spray systems. After the event, confirm gas levels are below project thresholds, examine for flyrock or mat movement, and scale loose rock to make the area safe. Retrieve monitoring data, compare readings to limits, and document any complaints or corrective actions. A concise, signed daily report pulls together permits, surveys, photos, and monitoring evidence for distribution.

- Inspect and tag mats; quarantine damaged units.

- Ensure full coverage and required overlap.

- Set and enforce exclusion zones with sentries.

- Measure wind speed and prepare dust control.

- Compile a signed daily report with evidence.

How to Use This Checklist On Your Project

- Preparation: assemble permits, approvals, pre-blast survey templates, calibrated seismographs, blast mats, anemometer, multi-gas monitor, radios, and PPE. Define receptors, vibration limits (mm/s), and responsibilities per approved project specifications and authority requirements.

- Open the interactive checklist, enter project metadata (location, permit numbers, limits), upload the monitoring plan, and add receptor and exclusion-zone maps. Preload mat IDs and equipment certifications.

- During field activities, tick each item, attach geotagged photos, calibration certificates, and setup screenshots. Use comments to capture decisions, constraints, and approvals from supervisors or authorities.

- Import seismograph files after events, review PPV and air overpressure, mark pass/fail against limits, and flag any exceedances for corrective action and stakeholder notification.

- Export the completed record as PDF/Excel and share via QR code for quick verification. Include photos, plots, signatures, and time stamps for traceability.

- Sign-Off: obtain digital signatures from the supervisor, blasting lead, and client/owner’s representative. Archive the report in the project folder with version control.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Rock Excavation & Controlled Splitting Checklist

- Download PDF - Rock Excavation & Controlled Splitting Checklist

- View Image - Rock Excavation & Controlled Splitting Checklist

Cite & Embed

“Rock Excavation & Controlled Splitting Checklist by Quollnet”

with a link to

this source page.