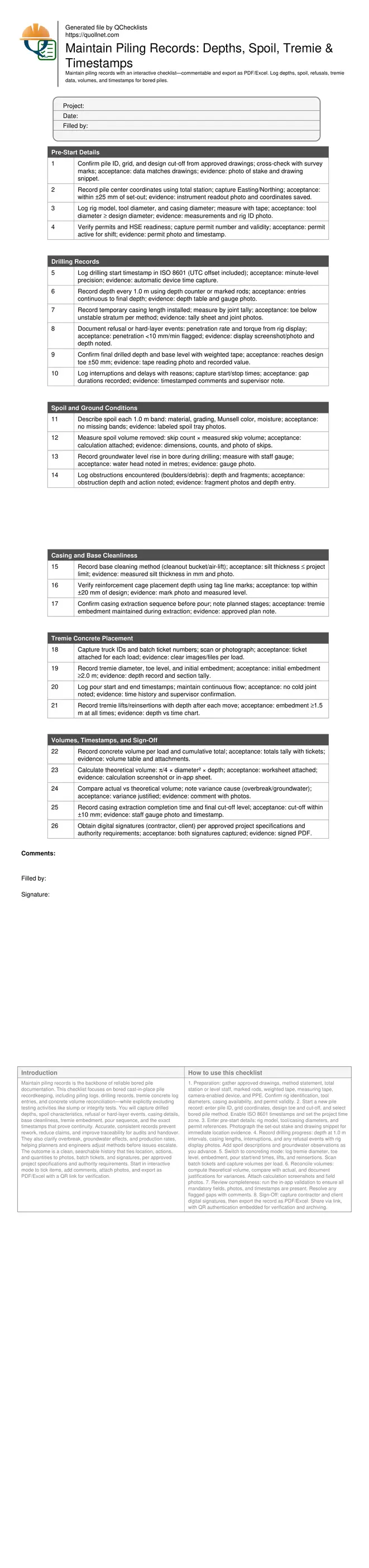

Maintain Piling Records: Depths, Spoil, Tremie & Timestamps

Definition: Maintain piling records for bored cast-in-place piles to guide site engineers and supervisors in logging depths, spoil, refusals, volumes, tremie operations, and timestamps, ensuring traceable, specification-compliant foundation documentation.

- Capture depths, soil descriptions, tremie actions, and concrete volumes in SI units.

- Reduce disputes with time-stamped, photo-backed evidence and calculation transparency.

- Follow methodical steps for refusals, casing, base clean, and sequence control.

- Interactive, commentable, export-ready checklist secured by QR code.

Maintain piling records is the backbone of reliable bored pile documentation. This checklist focuses on bored cast-in-place pile recordkeeping, including piling logs, drilling records, tremie concrete log entries, and concrete volume reconciliation—while explicitly excluding testing activities like slump or integrity tests. You will capture drilled depths, spoil characteristics, refusal or hard-layer events, casing details, base cleanliness, tremie embedment, pour sequence, and the exact timestamps that prove continuity. Accurate, consistent records prevent rework, reduce claims, and improve traceability for audits and handover. They also clarify overbreak, groundwater effects, and production rates, helping planners and engineers adjust methods before issues escalate. The outcome is a clean, searchable history that ties location, actions, and quantities to photos, batch tickets, and signatures, per approved project specifications and authority requirements. Start in interactive mode to tick items, add comments, attach photos, and export as PDF/Excel with a QR link for verification.

- Create a consistent, auditable pile log that covers drilled depths at defined intervals, spoil descriptions with photographic evidence, casing lengths, base cleaning results, and tremie operations with continuous embedment records, supported by precise ISO 8601 timestamps and location references for each pile.

- Reconcile theoretical and actual concrete volumes using transparent formulas and field measurements, then highlight variances alongside causes such as overbreak, groundwater inflow, or obstructions. Attach batch tickets, rig display photos, and supervisor notes to build a defensible record that meets project documentation requirements.

- Interactive online checklist with tick, comment, and export features secured by QR code. Use it to assign actions, track pour sequence and durations, and share signed summaries instantly with stakeholders, ensuring consistent formats, SI units, and traceable data from excavation start to final cut-off.

Pre-Start Details

Drilling Records

Spoil and Ground Conditions

Casing and Base Cleanliness

Tremie Concrete Placement

Volumes, Timestamps, and Sign-Off

Why meticulous bored pile records matter

Accurate records transform piling from opaque activity to traceable, defensible work. Use SI units, clear photos, and ISO 8601 timestamps for every stage—from drilling start to final cut-off. Tie each entry to a unique pile ID and grid so location, time, and action are unambiguous. Capture spoil descriptions at consistent intervals to reveal stratigraphy changes that influence stability and volumes. Document casing lengths and base cleaning results to demonstrate readiness for tremie placement. During pours, keep tremie embedment continuous and log every lift and re-insertion to avoid breaks in head. Variances between theoretical and actual volumes are inevitable; quantify them, add context (overbreak, groundwater inflow), and attach evidence. These practices reduce disputes, enable rapid reviews, and satisfy documentation requirements per approved project specifications and authority requirements.

- Use ISO 8601 timestamps with UTC offset.

- Capture photos for depth, spoil, and tickets.

- Record depth at consistent 1.0 m intervals.

- Reference drawing IDs and grid coordinates.

- Summarize variances with clear justifications.

Depths, refusals, and ground conditions

Depth logging should follow a predictable cadence that matches the tool and geology. Measure with marked rods or a reliable depth counter, and confirm final depth using a weighted tape. When penetration slows sharply, record torque and penetration rate from the rig display to evidence refusal or hard layers. Spoil logs must include material, grading, color, and moisture, photographed in labeled trays. Groundwater observations are vital: note water head in metres and any sudden inflows that can inflate concrete usage. Obstruction encounters should be supported with fragment photos and depth entries. Consistency across these records lets reviewers evaluate overbreak risks, casing necessity, and the adequacy of base cleaning before concreting begins.

- Log torque spikes with associated depth.

- Photograph and label spoil every metre.

- Measure groundwater head in metres.

- Confirm final depth with weighted tape.

- Note obstruction depth and action taken.

Tremie placement, volumes, and reconciliation

Tremie concrete placement depends on maintaining embedment to prevent segregation. Record tremie diameter, toe level, and embedment before the first concrete charge. Log pour start and end times to prove continuity. Every tremie lift or re-insertion must include the new depth and resulting embedment. Capture truck IDs and batch ticket numbers to link loads to volumes. Reconcile total placed volume against theoretical volume, then explain variances using field observations: overbreak, cavities, or groundwater entry. Attach time histories, depth charts, and photos of gauges. This mass-balance approach reveals anomalies early and creates robust evidence for handover packages without relying on separate testing data.

- Maintain tremie embedment continuously.

- Attach batch tickets for every load.

- Chart depth versus time during lifts.

- Explain volume variances with context.

- Export reconciled summary for review.

How to Maintain Piling Records with This Checklist

- Preparation: gather approved drawings, method statement, total station or level staff, marked rods, weighted tape, measuring tape, camera-enabled device, and PPE. Confirm rig identification, tool diameters, casing availability, and permit validity.

- Start a new pile record: enter pile ID, grid coordinates, design toe and cut-off, and select bored pile method. Enable ISO 8601 timestamps and set the project time zone.

- Enter pre-start details: rig model, tool/casing diameters, and permit references. Photograph the set-out stake and drawing snippet for immediate location evidence.

- Record drilling progress: depth at 1.0 m intervals, casing lengths, interruptions, and any refusal events with rig display photos. Add spoil descriptions and groundwater observations as you advance.

- Switch to concreting mode: log tremie diameter, toe level, embedment, pour start/end times, lifts, and reinsertions. Scan batch tickets and capture volumes per load.

- Reconcile volumes: compute theoretical volume, compare with actual, and document justifications for variances. Attach calculation screenshots and field photos.

- Review completeness: run the in-app validation to ensure all mandatory fields, photos, and timestamps are present. Resolve any flagged gaps with comments.

- Sign-Off: capture contractor and client digital signatures, then export the record as PDF/Excel. Share via link, with QR authentication embedded for verification and archiving.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Piling Records Maintenance (Bored Piles)

- Download PDF - Piling Records Maintenance (Bored Piles)

- View Image - Piling Records Maintenance (Bored Piles)