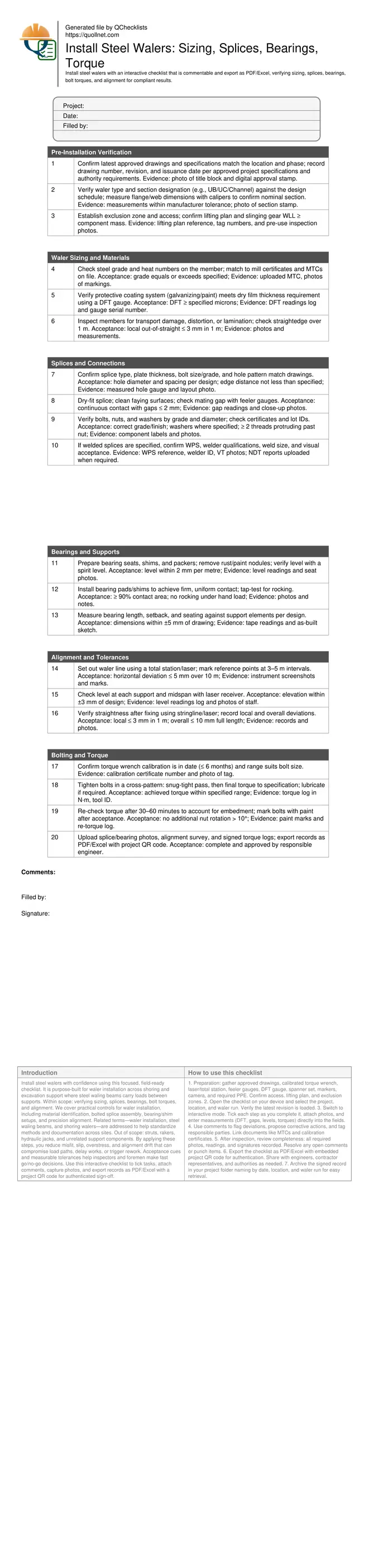

Install Steel Walers Checklist: Sizing, Splices, Bearings, Torque

Definition: Install steel walers checklist for site engineers verifies sizing, splices, bearings, bolt torques, and alignment, guiding compliant installation for temporary or permanent waling beams without struts or rakers.

- Confirm correct sections, grade, and length from approved drawings.

- Inspect splices and bearings to achieve designed load paths.

- Torque bolts to specification; document readings with calibrated tools.

- Interactive, commentable, export, and QR code for secure sign-off.

Install steel walers with confidence using this focused, field-ready checklist. It is purpose-built for waler installation across shoring and excavation support where steel waling beams carry loads between supports. Within scope: verifying sizing, splices, bearings, bolt torques, and alignment. We cover practical controls for waler installation, including material identification, bolted splice assembly, bearing/shim setups, and precision alignment. Related terms—waler installation, steel waling beams, and shoring walers—are addressed to help standardize methods and documentation across sites. Out of scope: struts, rakers, hydraulic jacks, and unrelated support components. By applying these steps, you reduce misfit, slip, overstress, and alignment drift that can compromise load paths, delay works, or trigger rework. Acceptance cues and measurable tolerances help inspectors and foremen make fast go/no-go decisions. Use this interactive checklist to tick tasks, attach comments, capture photos, and export records as PDF/Excel with a project QR code for authenticated sign-off.

- Ensure walers match design sizing and material grade, confirm splice detailing, check bearing seating and shims, and record calibrated bolt torques. Reduce rework by catching mismatches and assembly gaps before loading the system.

- Verify alignment with laser or total station, documenting straightness, level, and offsets within practical tolerances. Capture photographs of splice faces, bearing contact areas, and final torque marks for traceable evidence.

- Interactive online checklist with tick, comment, and export features secured by QR code. Field teams can add photos, torque logs, and as-built sketches, then share authenticated records with engineers and authorities instantly.

- Standardize inspection steps across crews and shifts: pre-installation verification, material checks, splice assembly, bearing setup, precision alignment, and torque control. Improve safety margins and compliance with clear acceptance criteria.

Pre-Installation Verification

Waler Sizing and Materials

Splices and Connections

Bearings and Supports

Alignment and Tolerances

Bolting and Torque

Right-Sizing Walers and Verifying Materials

Correct waler sizing underpins safe load transfer. Start by confirming the section designation and steel grade against the design schedule. Measure key dimensions to verify you received the intended member, and compare heat numbers to mill certificates. Coatings matter too: galvanized or painted walers should meet the specified dry film thickness to prevent corrosion during service. Inspect for transport bends, dents, or twists; minor damage can create stress risers or misalignment later. Acceptance cues include grade equal to or better than specified, DFT at or above the target, and straightness within a few millimetres over practical gauges. Recording evidence—photos of stamps, DFT readings, and dimensional checks—builds traceability and speeds engineer acceptance. By resolving mismatches before lifting, crews avoid rework at height and keep crane time productive. These steps keep the installation sequence smooth and safeguard designed capacities without last-minute material substitutions or undocumented deviations.

- Match section and grade to drawings and certificates.

- Confirm DFT with a calibrated gauge and record readings.

- Reject members with excessive twist or dents.

- Photograph markings and upload mill test certificates.

Splices and Bearings for Reliable Load Paths

Splices and bearings are where installation quality most affects structural performance. Clean faying surfaces and dry-fit splice plates before tightening. Aim for near-continuous contact so bolt preload does real work, not bridging gaps. Check edge distances and hole patterns; they control bearing and tear-out capacity. At bearings, prepare level, clean seats and set shim stacks or pads to distribute loads evenly. Measure bearing lengths and setbacks to avoid unintended eccentricities that amplify bolt demands. Acceptance cues include tight faying surfaces, correct bolt grade and projection, and uniform seating with minimal rocking. When welds are specified, ensure qualified procedures and documentation. Record torque with calibrated tools and re‑check after short relaxation. Good documentation and photos at these details validate the load path and help engineers sign off quickly.

- Surface contact: gaps ≤ 2 mm at splices.

- Edge distances meet specified minimums.

- Uniform bearing with ≥ 90% contact area.

- Use calibrated tools and retain torque logs.

Precision Alignment and Repeatable Torque Control

Alignment governs how loads share between walers and supports. Use a laser or total station to set line and level before final tightening, and re-check straightness after bolts are brought to torque. Practical targets keep work efficient: millimetres over metres rather than zero tolerance. Document horizontal deviation, elevation, and offsets so the as-built can be compared to design. Torque control transforms bolted splices from loose fit-ups to reliable friction connections. Work in a cross-pattern: snug first, then final torque, then a short break and re-torque to overcome embedment. Marking bolts after acceptance helps future inspectors. By combining survey-grade alignment with consistent fastening practice, you minimize slip, prevent prying action, and avoid post-load surprises that can slow excavation or backfilling sequences.

- Set line with laser; verify at 3–5 m intervals.

- Elevation within practical millimetre tolerances.

- Cross-pattern tightening and timed re-torque.

- Paint-mark bolts after acceptance for traceability.

How to Use This Install Steel Walers Checklist

- Preparation: gather approved drawings, calibrated torque wrench, laser/total station, feeler gauges, DFT gauge, spanner set, markers, camera, and required PPE. Confirm access, lifting plan, and exclusion zones.

- Open the checklist on your device and select the project, location, and waler run. Verify the latest revision is loaded.

- Switch to interactive mode. Tick each step as you complete it, attach photos, and enter measurements (DFT, gaps, levels, torques) directly into the fields.

- Use comments to flag deviations, propose corrective actions, and tag responsible parties. Link documents like MTCs and calibration certificates.

- After inspection, review completeness: all required photos, readings, and signatures recorded. Resolve any open comments or punch items.

- Export the checklist as PDF/Excel with embedded project QR code for authentication. Share with engineers, contractor representatives, and authorities as needed.

- Archive the signed record in your project folder naming by date, location, and waler run for easy retrieval.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Install Steel Walers Inspection

- Download PDF - Install Steel Walers Inspection

- View Image - Install Steel Walers Inspection