Glazing and Hardware Installation Inspection Checklist

This comprehensive checklist is designed to guide professionals through the inspection of glazing and hardware installations. Ensuring that glazing and hardware are correctly installed is critical to the performance, safety, and longevity of any structure. This checklist provides a structured approach to inspect these elements, helping to identify potential issues early and ensure compliance with industry standards. Whether you are a contractor, site manager, or quality assurance officer, this checklist will assist you in maintaining high standards of workmanship and safety.

- Ensure safety and compliance: This checklist helps in adhering to industry standards for glazing and hardware installations.

- Identify issues early: Systematic inspections reduce the risk of costly repairs by catching problems early.

- Improve quality assurance: Consistent use of this checklist ensures high-quality workmanship and performance.

- Enhance durability: Proper inspections contribute to the longevity and durability of installations.

- Streamline processes: A structured approach saves time and improves efficiency during inspections.

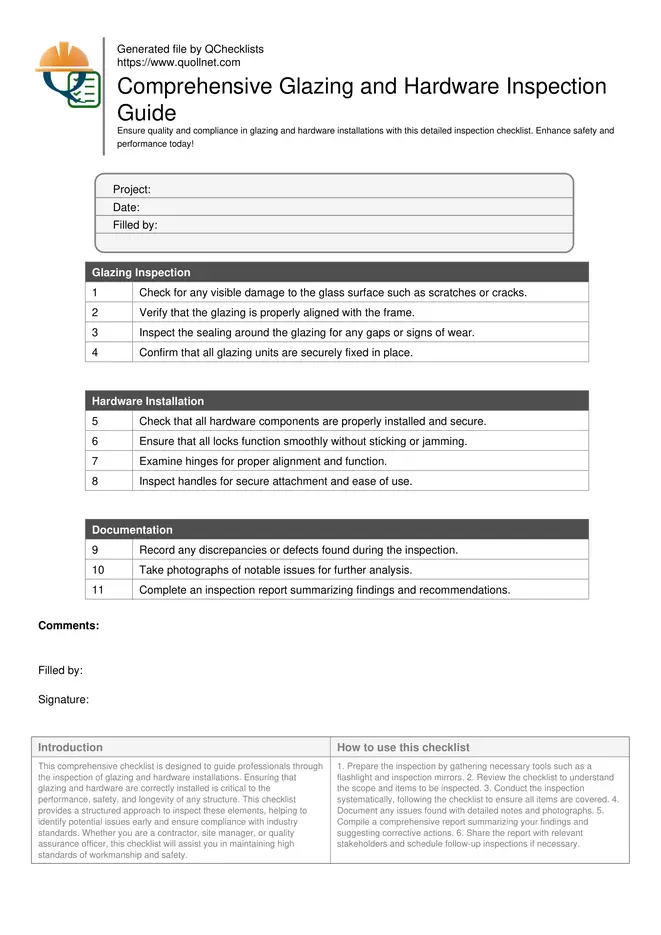

Glazing Inspection

Hardware Installation

Documentation

Understanding Glazing Inspection

Inspecting glazing installations involves checking for proper alignment, secure fixing, and seal integrity. These inspections are crucial as glazing failures can lead to energy inefficiency and safety hazards. A thorough inspection will ensure that the glass is free from defects and correctly fitted. Inspectors should be familiar with common types of glazing and the specific requirements for each to ensure comprehensive evaluations.

- Check for visible defects such as cracks or scratches.

- Ensure correct alignment and secure fixing.

- Verify seal integrity to prevent air and moisture infiltration.

Hardware Installation Checks

Hardware installations must be carefully inspected to ensure functionality and safety. This includes checking handles, locks, hinges, and any other hardware components. Proper functioning of these elements is essential for the security and usability of the installation. Inspectors should ensure that all hardware is installed as per the manufacturer’s specifications and that they operate smoothly without obstruction.

- Ensure all hardware is securely fastened.

- Test the functionality of locks and handles.

- Check for any signs of wear or damage.

How to Use the Glazing and Hardware Installation Checklist

- Prepare the inspection by gathering necessary tools such as a flashlight and inspection mirrors.

- Review the checklist to understand the scope and items to be inspected.

- Conduct the inspection systematically, following the checklist to ensure all items are covered.

- Document any issues found with detailed notes and photographs.

- Compile a comprehensive report summarizing your findings and suggesting corrective actions.

- Share the report with relevant stakeholders and schedule follow-up inspections if necessary.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Glazing and Hardware Installation Inspection Checklist

- Download PDF - Glazing and Hardware Installation Inspection Checklist

- View Image - Glazing and Hardware Installation Inspection Checklist