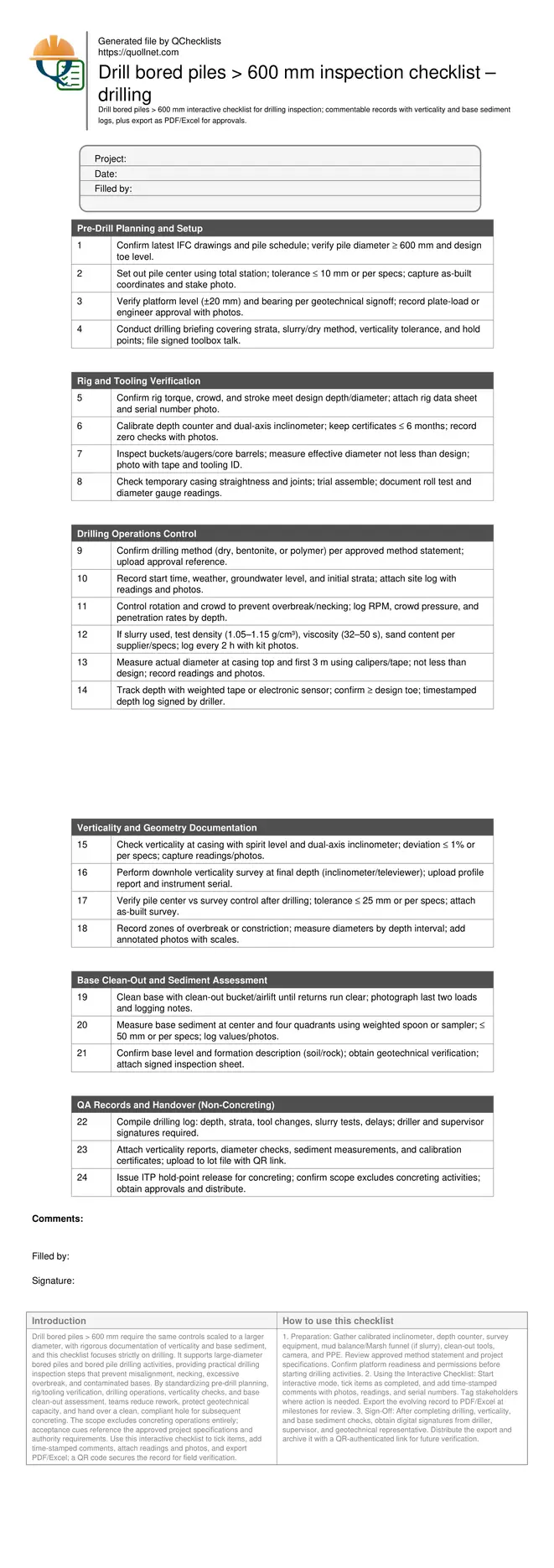

Drill bored piles > 600 mm – inspection checklist (drilling)

Definition: Drill bored piles > 600 mm inspection checklist guides drilling controls and documentation for large-diameter piles before concreting, emphasizing verticality measurement, base sediment logging, and scaled QA tolerances for supervisors.

- Apply same controls scaled for larger diameter and deeper sockets.

- Document verticality and alignment with calibrated instruments and survey.

- Measure base sediment thickness at center and quadrants with evidence.

- Interactive, commentable records with export and QR code verification.

Drill bored piles > 600 mm require the same controls scaled to a larger diameter, with rigorous documentation of verticality and base sediment, and this checklist focuses strictly on drilling. It supports large-diameter bored piles and bored pile drilling activities, providing practical drilling inspection steps that prevent misalignment, necking, excessive overbreak, and contaminated bases. By standardizing pre-drill planning, rig/tooling verification, drilling operations, verticality checks, and base clean-out assessment, teams reduce rework, protect geotechnical capacity, and hand over a clean, compliant hole for subsequent concreting. The scope excludes concreting operations entirely; acceptance cues reference the approved project specifications and authority requirements. Use this interactive checklist to tick items, add time-stamped comments, attach readings and photos, and export PDF/Excel; a QR code secures the record for field verification.

- This drilling-only checklist scales familiar bored pile controls for diameters above 600 mm, emphasizing alignment, diameter confirmation, strata logging, and safe platform practices. It helps prevent overbreak, necking, and rig-induced deviations that compromise pile capacity and tolerance compliance.

- Focused on measurement and evidence, it captures calibrated verticality readings, as-built coordinates, diameter checks, depth logs, and slurry properties (if used). It also standardizes clean-out criteria and sediment thickness measurement across center and quadrants before handover for concreting.

- Interactive online checklist with tick, comment, and export features secured by QR code. Supervisors and inspectors attach photos, instrument serials, and signatures, creating a verifiable audit trail aligned with approved project specifications and authority requirements.

- By separating drilling from concreting, the checklist enforces a clear hold point. It delivers a documented, stable, and clean base, minimizing inclusion risk and ensuring the next activity proceeds on verified geometry and geotechnical formation without delay.

Pre-Drill Planning and Setup

Rig and Tooling Verification

Drilling Operations Control

Verticality and Geometry Documentation

Base Clean-Out and Sediment Assessment

QA Records and Handover (Non-Concreting)

Scaling Controls for Large-Diameter Drilling

When piles exceed 600 mm, the basic controls remain the same but must be scaled for higher torque, greater spoil volume, and increased sensitivity to platform flatness and casing straightness. A heavier rig magnifies site platform risks, so pre-drill verification of level and bearing is essential. Larger buckets and core barrels require vigilant wear checks to ensure the cut diameter meets design, while survey control must be precise to prevent cumulative layout drift across a pile group. If slurry is used, maintain tighter monitoring intervals because a larger hole volume can dilute properties quickly and elevate sand content. Recording RPM, crowd pressure, and penetration rates helps detect changing strata and overbreak risks. Consistent documentation across these aspects enables a clean, auditable handover for concreting without mixing scopes.

- Level, bearing, and exclusion zones protect heavy rig stability.

- Tool wear directly affects cut diameter; measure and photograph.

- Survey control precision prevents group misalignment.

- Slurry properties can drift faster in larger volumes.

Verticality, Alignment, and Evidence

Verticality determines load path efficiency and reinforcement fit, so measure it both at the casing head and downhole. A dual-axis inclinometer or downhole tool provides a profile through depth, while a spirit level confirms casing plumb. Accept verticality within specified tolerance (e.g., ≤ 1%) or per approved project specifications and authority requirements. Capture instrument serial numbers, calibration dates, and time-stamped readings. Cross-check alignment with an as-built survey to confirm pile center relative to grid control. Where deviations approach limits, note corrective actions (e.g., casing adjustment, tool change) before proceeding. Document any necking or overbreak with measured diameters by depth, and annotate photos with scales. These records protect design compliance and accelerate review during hold points.

- Use calibrated dual-axis inclinometer for downhole profiles.

- Record instrument serials and zero-check photos.

- Confirm pile center with as-built survey coordinates.

- Log any necking or overbreak with dimensions.

Base Clean-Out and Sediment Measurement

A clean pile base is vital for bond and end bearing. After achieving final depth, perform clean-out using an appropriate bucket or airlift until returns are visually clear and free from debris. Then measure base sediment thickness at the center and four quadrants using a weighted spoon or sampler. Acceptable thickness should meet project specifications (commonly ≤ 50 mm), with each reading logged against depth and location. If slurry is present, confirm its final density, viscosity, and sand content meet the acceptance window before handover, as poor slurry can redeposit fines. Have the geotechnical representative verify formation type and toe level. Provide clear photographic evidence of clean-out results, sampling tools in use, and logs. This documented process reduces inclusion risk and provides confidence for the subsequent concreting operation.

- Clean until returns are clear and consistent.

- Measure sediment at center and four quadrants.

- Record slurry properties at final state if used.

- Obtain geotechnical verification of formation.

How to Use This Checklist

- Preparation: Gather calibrated inclinometer, depth counter, survey equipment, mud balance/Marsh funnel (if slurry), clean-out tools, camera, and PPE. Review approved method statement and project specifications. Confirm platform readiness and permissions before starting drilling activities.

- Using the Interactive Checklist: Start interactive mode, tick items as completed, and add time-stamped comments with photos, readings, and serial numbers. Tag stakeholders where action is needed. Export the evolving record to PDF/Excel at milestones for review.

- Sign-Off: After completing drilling, verticality, and base sediment checks, obtain digital signatures from driller, supervisor, and geotechnical representative. Distribute the export and archive it with a QR-authenticated link for future verification.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Drill Bored Piles > 600 mm – Drilling Inspection

- Download PDF - Drill Bored Piles > 600 mm – Drilling Inspection

- View Image - Drill Bored Piles > 600 mm – Drilling Inspection