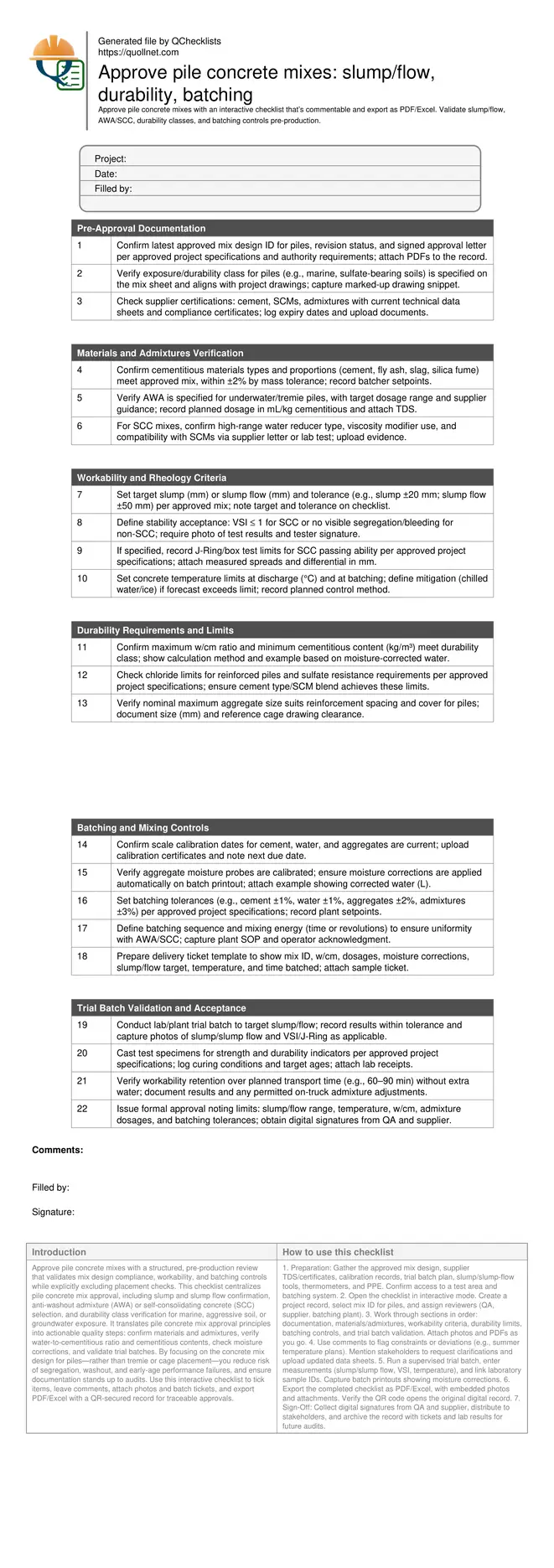

Approve pile concrete mixes: slump/flow, AWA/SCC, durability, batching

Definition: Approve pile concrete mixes with this QC checklist to validate slump/flow, AWA/SCC use, durability classes, and batching controls before production, excluding placement checks for a clean, spec-compliant approval path.

- Confirm slump/slump-flow targets and stability before any site delivery.

- Verify AWA or SCC selection, dosage, and compatibility with materials.

- Check durability class limits, w/cm, and cementitious content compliance.

- Interactive, commentable checklist with export and QR code traceability.

Approve pile concrete mixes with a structured, pre-production review that validates mix design compliance, workability, and batching controls while explicitly excluding placement checks. This checklist centralizes pile concrete mix approval, including slump and slump flow confirmation, anti-washout admixture (AWA) or self-consolidating concrete (SCC) selection, and durability class verification for marine, aggressive soil, or groundwater exposure. It translates pile concrete mix approval principles into actionable quality steps: confirm materials and admixtures, verify water-to-cementitious ratio and cementitious contents, check moisture corrections, and validate trial batches. By focusing on the concrete mix design for piles—rather than tremie or cage placement—you reduce risk of segregation, washout, and early-age performance failures, and ensure documentation stands up to audits. Use this interactive checklist to tick items, leave comments, attach photos and batch tickets, and export PDF/Excel with a QR-secured record for traceable approvals.

- Use a pre-production checklist to approve pile concrete mixes by validating slump/slump flow, AWA/SCC selection, durability classes, and batching controls, ensuring conformity to the approved project specifications and authority requirements before delivery.

- Confirm workability and stability via trial batches, slump flow or slump, visual stability assessments, temperature limits, and admixture compatibility. Capture objective evidence—photos, readings, batch printouts, and signatures—for dependable audit readiness.

- Verify durability class requirements, including maximum water-to-cementitious ratio, minimum cementitious content, sulfate/chloride limits, and SCM proportions. This reduces long-term deterioration risks in marine and aggressive groundwater environments.

- Interactive online checklist with tick, comment, and export features secured by QR code. Share approvals with stakeholders, lock records with digital signatures, and archive batch tickets, test data, and supplier certificates for full traceability.

Pre-Approval Documentation

Materials and Admixtures Verification

Workability and Rheology Criteria

Durability Requirements and Limits

Batching and Mixing Controls

Trial Batch Validation and Acceptance

Workability and Stability for Pile Mixes: Slump, Slump Flow, and AWA/SCC

Pile concretes demand predictable workability and stability. For conventional mixes, slump must land within a tight tolerance to balance pumpability and cohesion. SCC pile mixes rely on slump flow and passing tests to confirm self-placing behavior without blockage. Anti-washout admixture (AWA) is vital for underwater or tremie concreting; it increases cohesion to resist washout without sacrificing flow when paired with proper high-range water reducers. Define acceptance up front: slump or slump flow targets, Visual Stability Index (VSI), and any J-Ring/box limits per approved project specifications and authority requirements. Control temperature because rheology shifts quickly in heat; plan chilled water or ice if needed. Validate these parameters during a supervised trial batch and again at production start. Require photos, measurements, and tester signatures so judgments are objective and repeatable. This approach avoids segregation, honeycombing, and washout while preserving steel encapsulation and pile section integrity.

- Set slump/slump flow targets with clear tolerances and evidence.

- Use AWA for underwater/tremie piles; confirm dosage and TDS.

- Confirm SCC passing ability and stability (VSI ≤ 1).

- Plan temperature controls; record actual °C at tests.

- Capture photos and signatures for every workability test.

Durability Classes and Proportioning to Resist Aggressive Environments

Piles often face marine chlorides, sulfates, and fluctuating groundwater. Assign the correct durability class early and lock key limits: maximum water-to-cementitious ratio, minimum cementitious content, chloride limits for reinforcement protection, and sulfate resistance. Select cement and SCM blends that deliver low permeability and chemical resistance while maintaining workable rheology. Ensure nominal maximum aggregate size suits cage spacing and cover to reduce blockage risk and voids. For SCC, balance paste volume and viscosity to improve passing while preventing segregation. Document the calculation method for w/cm using moisture-corrected water; it is a common audit gap. These durability checks occur during mix approval, not during placement, and they underpin long-term pile performance, reducing corrosion, cracking, and serviceability issues. Keep supplier letters and lab data attached so the approval is defensible and traceable throughout the project lifecycle.

- Confirm durability class and key limits on the mix sheet.

- Verify w/cm calculation uses moisture-corrected water.

- Choose SCMs to meet chloride/sulfate resistance goals.

- Check aggregate size vs. cage spacing and cover.

- Attach supporting lab data and supplier letters.

Batching Controls, Moisture Corrections, and Traceable Documentation

Robust batching prevents drift from approved proportions. Verify calibration of scales and moisture probes, and set tolerances that the plant can reliably hold. Moisture correction is critical; uncorrected aggregates push w/cm above limits. Require batch printouts showing corrected water content, admixture dosages, and actual masses within tolerance. Define a mixing sequence and energy that suit AWA/SCC so admixtures disperse uniformly without over-shearing. Standardize delivery tickets to include mix ID, w/cm, target slump/flow, batch time, temperature, and truck ID for traceability. Trial batches validate these controls before production by demonstrating workability, stability, and early-age performance. Finally, issue a formal approval capturing boundaries—slump/flow, temperature, w/cm, dosages, and tolerances—so dispatch and site teams have one authoritative reference.

- Keep calibrations current and attach certificates.

- Show moisture-corrected water on batch printouts.

- Define mixing sequence and energy for AWA/SCC.

- Standardize delivery ticket data fields.

- Publish a signed approval with clear limits.

How to Use This Interactive Pile Concrete Mix Approval Checklist

- Preparation: Gather the approved mix design, supplier TDS/certificates, calibration records, trial batch plan, slump/slump-flow tools, thermometers, and PPE. Confirm access to a test area and batching system.

- Open the checklist in interactive mode. Create a project record, select mix ID for piles, and assign reviewers (QA, supplier, batching plant).

- Work through sections in order: documentation, materials/admixtures, workability criteria, durability limits, batching controls, and trial batch validation. Attach photos and PDFs as you go.

- Use comments to flag constraints or deviations (e.g., summer temperature plans). Mention stakeholders to request clarifications and upload updated data sheets.

- Run a supervised trial batch, enter measurements (slump/slump flow, VSI, temperature), and link laboratory sample IDs. Capture batch printouts showing moisture corrections.

- Export the completed checklist as PDF/Excel, with embedded photos and attachments. Verify the QR code opens the original digital record.

- Sign-Off: Collect digital signatures from QA and supplier, distribute to stakeholders, and archive the record with tickets and lab results for future audits.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Pile Concrete Mix Approval

- Download PDF - Pile Concrete Mix Approval

- View Image - Pile Concrete Mix Approval

Cite & Embed

“Pile Concrete Mix Approval by Quollnet”

with a link to

this source page.