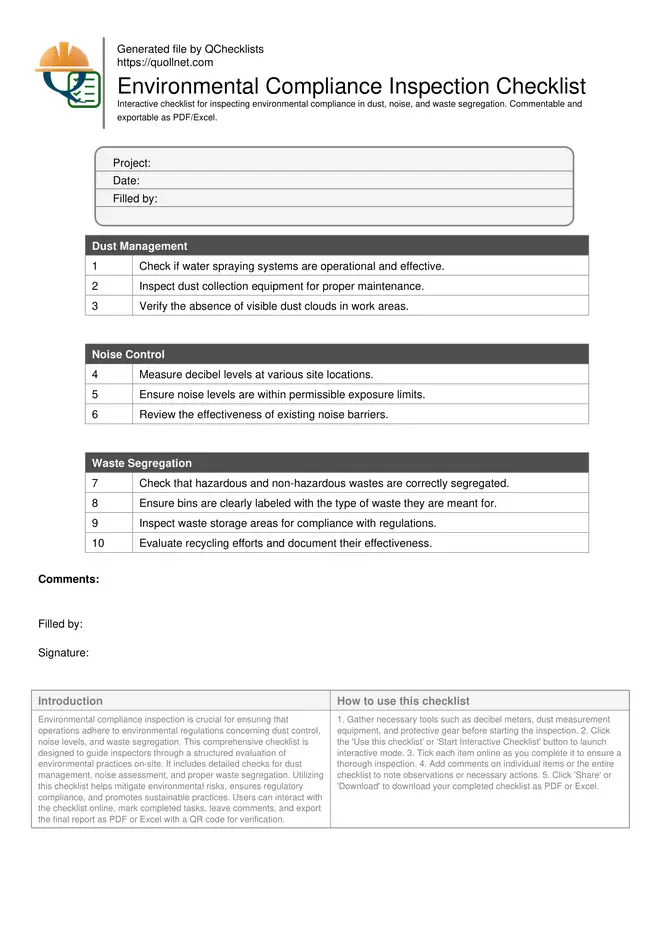

Environmental Compliance Inspection Checklist

Environmental compliance inspection is crucial for ensuring that operations adhere to environmental regulations concerning dust control, noise levels, and waste segregation. This comprehensive checklist is designed to guide inspectors through a structured evaluation of environmental practices on-site. It includes detailed checks for dust management, noise assessment, and proper waste segregation. Utilizing this checklist helps mitigate environmental risks, ensures regulatory compliance, and promotes sustainable practices. Users can interact with the checklist online, mark completed tasks, leave comments, and export the final report as PDF or Excel with a QR code for verification.

- Ensure compliance with environmental regulations through detailed inspections of dust, noise, and waste management.

- Promote sustainable practices by identifying and rectifying environmental hazards on-site.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Facilitate effective communication and documentation with downloadable PDF and Excel reports.

Dust Management

Noise Control

Waste Segregation

Dust Control Measures

Dust control is vital in preventing air pollution and health hazards. During inspections, assess the adequacy of dust suppression methods, such as water spraying and dust collectors. Evaluate the effectiveness of these techniques in reducing airborne particles and ensure they meet regulatory standards. Proper dust management not only complies with laws but also protects workers' health and the surrounding environment.

- Check for active dust suppression systems.

- Ensure equipment is functioning correctly.

- Verify compliance with local dust regulations.

- Inspect for visible dust clouds.

- Assess worker exposure to dust particles.

Noise Level Assessment

Noise pollution can have significant impacts on both workers and nearby communities. Conduct thorough noise assessments to measure decibel levels across different areas of the site. Compare findings against permissible exposure limits to ensure compliance. Effective noise management reduces potential health risks and enhances the working environment. Implementing noise reduction strategies demonstrates a commitment to environmental stewardship.

- Measure noise levels in high-activity areas.

- Compare readings to established noise limits.

- Check for noise reduction measures.

- Assess the effectiveness of acoustic barriers.

- Review worker noise exposure records.

Waste Segregation Practices

Proper waste segregation is essential for minimizing environmental impact and facilitating recycling efforts. During inspections, evaluate how waste is sorted and stored. Ensure that hazardous materials are handled separately and disposed of according to environmental guidelines. Effective waste management practices not only comply with regulations but also contribute to sustainability by reducing landfill use and promoting recycling.

- Inspect waste segregation procedures.

- Ensure separate bins for hazardous waste.

- Verify labels and signage for waste types.

- Check for compliance with disposal regulations.

- Assess recycling efforts and effectiveness.

How to Use the Environmental Compliance Checklist

- Gather necessary tools such as decibel meters, dust measurement equipment, and protective gear before starting the inspection.

- Click the 'Use this checklist' or 'Start Interactive Checklist' button to launch interactive mode.

- Tick each item online as you complete it to ensure a thorough inspection.

- Add comments on individual items or the entire checklist to note observations or necessary actions.

- Click 'Share' or 'Download' to download your completed checklist as PDF or Excel.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Environmental Compliance Inspection

- Download PDF - Environmental Compliance Inspection

- View Image - Environmental Compliance Inspection