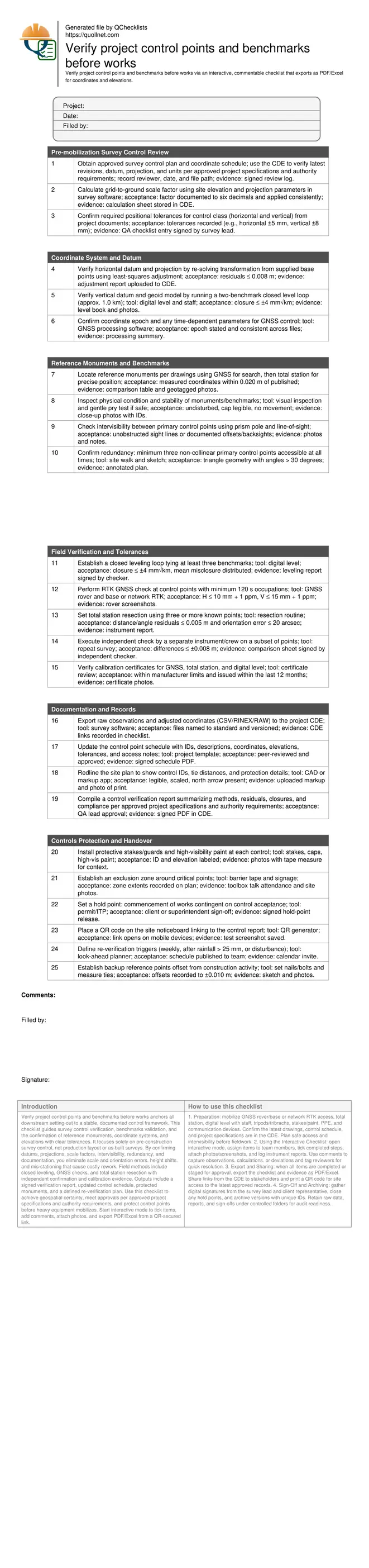

Verify project control points and benchmarks before works

Definition: Verify project control points and benchmarks before works is a pre-construction survey QA checklist for site engineers and surveyors to confirm coordinates, elevations, tolerances, monuments, and documentation.

- Confirm coordinates, elevations, datums, projections, and scale factors.

- Reduce layout risk by validating control network accuracy and redundancy.

- Use GNSS, total station, and leveling with documented tolerances.

- Interactive, commentable checklist; export and QR code for verification.

Verify project control points and benchmarks before works anchors all downstream setting-out to a stable, documented control framework. This checklist guides survey control verification, benchmarks validation, and the confirmation of reference monuments, coordinate systems, and elevations with clear tolerances. It focuses solely on pre-construction survey control, not production layout or as-built surveys. By confirming datums, projections, scale factors, intervisibility, redundancy, and documentation, you eliminate scale and orientation errors, height shifts, and mis-stationing that cause costly rework. Field methods include closed leveling, GNSS checks, and total station resection with independent confirmation and calibration evidence. Outputs include a signed verification report, updated control schedule, protected monuments, and a defined re-verification plan. Use this checklist to achieve geospatial certainty, meet approvals per approved project specifications and authority requirements, and protect control points before heavy equipment mobilizes. Start interactive mode to tick items, add comments, attach photos, and export PDF/Excel from a QR-secured link.

- This checklist verifies datums, projections, coordinates, elevations, and tolerances, then confirms redundancy, intervisibility, and calibration evidence before work starts. The result is a stable, documented control network that prevents scale, height, and orientation mistakes that propagate through setting-out and cause rework and claims.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Detailed field methods—closed leveling, RTK checks, and total station resection—produce measurable acceptance (e.g., residuals, closures, positional tolerances). Signed reports, updated control schedules, and protected monuments create defensible records for client acceptance and smooth mobilization.

Pre-mobilization Survey Control Review

Coordinate System and Datum

Reference Monuments and Benchmarks

Field Verification and Tolerances

Documentation and Records

Controls Protection and Handover

Build a robust control framework with clear acceptance criteria

Accurate works begin with a stable, redundant control framework built on the correct horizontal projection, vertical datum, and clearly documented scale factor. Select at least three non-collinear, intervisible primary points and confirm they are accessible throughout construction. Validate published coordinates with an adjustment that reports residuals, then lock tolerances for horizontal and vertical control so everyone aligns to the same acceptance thresholds. On sloping or expansive sites, grid-to-ground factors can shift distances enough to create layout gaps; documenting and consistently applying the factor prevents cumulative scale errors. Confirm intervisibility early so instrument setups are efficient and safe. Finally, ensure each monument is physically sound, labeled, and protected from plant and stockpiles. With this, you create a reference skeleton that withstands daily site pressures and informs every subsequent set-out.

- Use the correct datum, projection, and scale factor.

- Ensure three or more non-collinear, intervisible primary points.

- State horizontal and vertical tolerances up front.

- Confirm physical integrity and protection of all monuments.

Field verification methods that stand up to scrutiny

Combine complementary methods to validate control before works. Run closed level loops across multiple benchmarks to confirm vertical consistency, applying the closure rule (e.g., ±4 mm√km) and distributing misclosure. Use RTK GNSS to test the horizontal and vertical fit with clear residual thresholds, then perform a total station resection on at least three known points for a rigorous check of orientation and distance. An independent repeat by another crew or instrument reduces human and equipment bias. Capture instrument calibration certificates to prove measurement reliability. Document readings, residuals, and closures with screenshots and reports so results are reproducible. Watch for multipath near metal, incorrect prism heights, tripod settlement, and poor centering—small mistakes amplify during layout. The goal is not just numbers within tolerance but evidence that demonstrates a defensible process.

- Use closed loops for vertical control confirmation.

- Verify with RTK and total station resection.

- Perform an independent repeat check by another crew.

- Attach calibration certificates and instrument reports.

Documentation, protection, and governance before mobilization

Verification is complete only when records are organized, published, and protected. Update the control point schedule with IDs, descriptions, coordinates, elevations, and tolerance notes, then redline drawings to show control locations and tie distances. Export raw observations and adjusted results to the common data environment with clear versioning. Compile a concise verification report summarizing methods, residuals, and closures, and obtain QA approval per approved project specifications and authority requirements. Protect each control with stakes, paint, and signage, and set an exclusion zone where plant operates. Establish re-verification triggers—weekly, after heavy rain, or if disturbed—and publish them in the look-ahead plan. Finally, add a QR code link to the report so stakeholders can verify the latest approved control on site.

- Publish a signed verification report and control schedule.

- Redline drawings with IDs and tie distances.

- Protect controls and set exclusion zones.

- Define and publish re-verification triggers.

How to Use This Survey Control Verification Checklist

- Preparation: mobilize GNSS rover/base or network RTK access, total station, digital level with staff, tripods/tribrachs, stakes/paint, PPE, and communication devices. Confirm the latest drawings, control schedule, and project specifications are in the CDE. Plan safe access and intervisibility before fieldwork.

- Using the Interactive Checklist: open interactive mode, assign items to team members, tick completed steps, attach photos/screenshots, and log instrument reports. Use comments to capture observations, calculations, or deviations and tag reviewers for quick resolution.

- Export and Sharing: when all items are completed or staged for approval, export the checklist and evidence as PDF/Excel. Share links from the CDE to stakeholders and print a QR code for site access to the latest approved records.

- Sign-Off and Archiving: gather digital signatures from the survey lead and client representative, close any hold points, and archive versions with unique IDs. Retain raw data, reports, and sign-offs under controlled folders for audit readiness.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Survey Control Points and Benchmarks Verification

- Download PDF - Survey Control Points and Benchmarks Verification

- View Image - Survey Control Points and Benchmarks Verification