Thermal Insulation and Vapour-Barrier Inspection

Inspecting thermal insulation continuity and vapour-barrier installation is crucial in ensuring energy efficiency and preventing moisture-related issues in buildings. This inspection includes checking the integrity and proper installation of insulation materials and vapour barriers across all surfaces where they are applied. Completing this inspection helps to avoid heat loss, reduce energy costs, and prevent condensation that can lead to mold growth. Our interactive checklist allows users to tick off tasks, leave comments, and export the completed report with a QR code for authenticity.

- Ensure energy efficiency by verifying the proper installation of thermal insulation and vapour barriers.

- Prevent moisture issues by checking the continuity of vapour-barrier installation.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Reduce energy costs and prevent mold growth by ensuring effective insulation and moisture control.

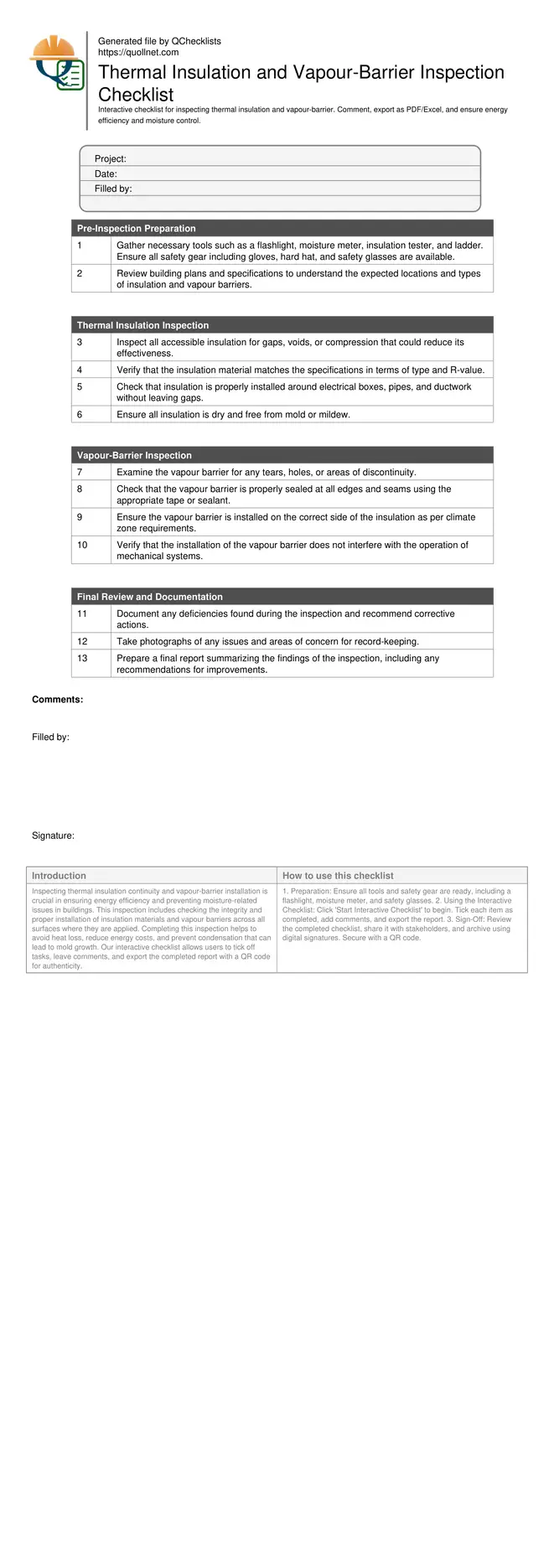

Pre-Inspection Preparation

Thermal Insulation Inspection

Vapour-Barrier Inspection

Final Review and Documentation

Understanding the Importance of Insulation Continuity

Ensuring thermal insulation continuity is essential for maintaining energy efficiency in buildings. Insulation must be continuous and without gaps to prevent heat loss and reduce energy consumption. During inspection, it is vital to check that the insulation is installed correctly around all structural and service penetrations, such as pipes and wires. This step is critical to avoid thermal bridging, which can occur when insulation is disrupted.

- Check for gaps and compression in insulation.

- Verify insulation around penetrations.

- Avoid thermal bridging by ensuring continuity.

- Match insulation type and R-value to specifications.

The Role of Vapour Barriers in Moisture Control

Vapour barriers play a crucial role in controlling moisture within a building structure. They prevent water vapor from entering the building envelope, which can lead to condensation and mold growth. During the inspection, verify that vapour barriers are intact and properly sealed. It is essential to ensure that they are installed on the correct side of the insulation to prevent moisture issues.

- Inspect for tears or holes in vapour barriers.

- Ensure vapour barriers are sealed at seams.

- Verify correct placement relative to insulation.

- Check compatibility with mechanical systems.

How to Use This Inspection Checklist

- Preparation: Ensure all tools and safety gear are ready, including a flashlight, moisture meter, and safety glasses.

- Using the Interactive Checklist: Click 'Start Interactive Checklist' to begin. Tick each item as completed, add comments, and export the report.

- Sign-Off: Review the completed checklist, share it with stakeholders, and archive using digital signatures. Secure with a QR code.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Thermal Insulation and Vapour-Barrier Inspection

- Download PDF - Thermal Insulation and Vapour-Barrier Inspection

- View Image - Thermal Insulation and Vapour-Barrier Inspection