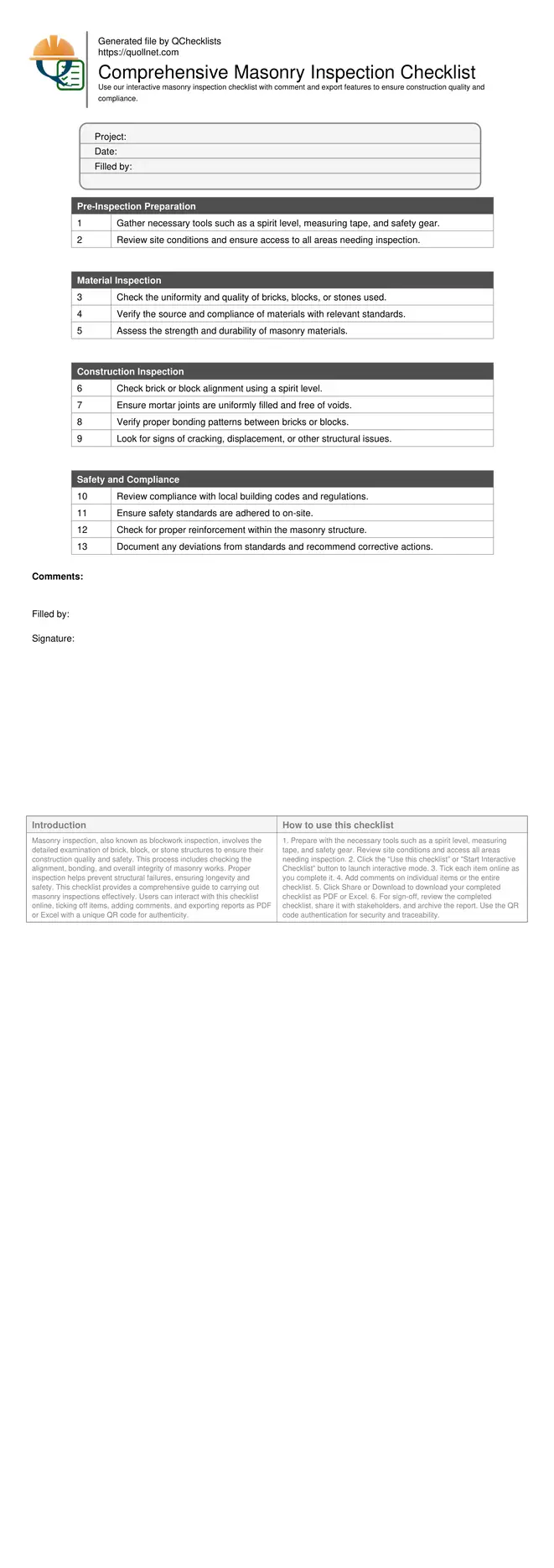

Masonry Inspection Checklist

Masonry inspection, also known as blockwork inspection, involves the detailed examination of brick, block, or stone structures to ensure their construction quality and safety. This process includes checking the alignment, bonding, and overall integrity of masonry works. Proper inspection helps prevent structural failures, ensuring longevity and safety. This checklist provides a comprehensive guide to carrying out masonry inspections effectively. Users can interact with this checklist online, ticking off items, adding comments, and exporting reports as PDF or Excel with a unique QR code for authenticity.

- Ensure structural integrity by checking alignment, bonding, and mortar joints.

- Identify potential issues early to prevent costly repairs.

- Guarantee compliance with building codes and standards.

- Interactive online checklist with tick, comment, and export features secured by QR code.

Pre-Inspection Preparation

Material Inspection

Construction Inspection

Safety and Compliance

Understanding Masonry Materials

Masonry materials such as bricks, blocks, and stones are the building blocks of many structures. Understanding their properties is crucial for effective inspection. Materials should be checked for uniformity, strength, and durability. Inspectors must be familiar with the specific characteristics of each material type used in a project.

- Check for material uniformity and quality.

- Verify the source and compliance of materials.

- Assess the strength and durability.

- Identify any visible defects or inconsistencies.

Inspecting Masonry Construction

During masonry inspection, focus on construction techniques and practices. Ensure that bricks or blocks are laid correctly, with proper alignment and bonding. Mortar joints should be even and well-filled to avoid structural weaknesses.

- Check brick or block alignment using a spirit level.

- Ensure mortar joints are uniformly filled.

- Verify proper bonding patterns.

- Inspect for any signs of cracking or displacement.

Safety and Compliance Checks

Ensuring compliance with safety standards and building codes is a vital part of masonry inspection. Inspectors should be well-versed in the relevant regulations and ensure that all aspects of the masonry work adhere to these guidelines.

- Review compliance with local building codes.

- Ensure safety standards are met on-site.

- Check for proper reinforcement within masonry.

- Document any deviations from standards.

How to Use the Masonry Inspection Checklist

- Prepare with the necessary tools such as a spirit level, measuring tape, and safety gear. Review site conditions and access all areas needing inspection.

- Click the “Use this checklist” or "Start Interactive Checklist" button to launch interactive mode.

- Tick each item online as you complete it.

- Add comments on individual items or the entire checklist.

- Click Share or Download to download your completed checklist as PDF or Excel.

- For sign-off, review the completed checklist, share it with stakeholders, and archive the report. Use the QR code authentication for security and traceability.