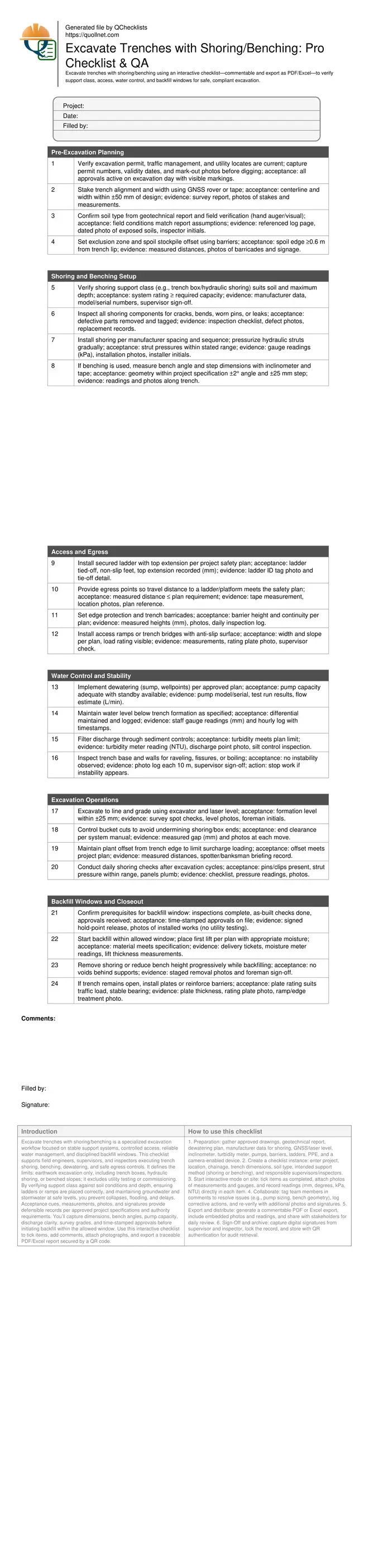

Excavate Trenches with Shoring/Benching: Pro Checklist & QA

Definition: Excavate trenches with shoring/benching checklist guides site supervisors and inspectors through verifying support class, safe access, water control, excavation execution, and backfill windows per approved project specifications and authority requirements.

- Confirm support class matches soil, depth, and load conditions.

- Establish safe access, egress, and exclusion zones with evidence.

- Control groundwater and surface inflow using pumps, sumps, discharge filters.

- Interactive, commentable checklist with export and QR code verification.

Excavate trenches with shoring/benching is a specialized excavation workflow focused on stable support systems, controlled access, reliable water management, and disciplined backfill windows. This checklist supports field engineers, supervisors, and inspectors executing trench shoring, benching, dewatering, and safe egress controls. It defines the limits: earthwork excavation only, including trench boxes, hydraulic shoring, or benched slopes; it excludes utility testing or commissioning. By verifying support class against soil conditions and depth, ensuring ladders or ramps are placed correctly, and maintaining groundwater and stormwater at safe levels, you prevent collapses, flooding, and delays. Acceptance cues, measurements, photos, and signatures provide defensible records per approved project specifications and authority requirements. You’ll capture dimensions, bench angles, pump capacity, discharge clarity, survey grades, and time-stamped approvals before initiating backfill within the allowed window. Use this interactive checklist to tick items, add comments, attach photographs, and export a traceable PDF/Excel report secured by a QR code.

- Field-proven sequence covering planning, shoring selection and inspection, access and egress, water control, excavation tolerances, and backfill windows, so crews avoid collapses, flooding, schedule slips, and rework while capturing photo and signature evidence for traceable compliance.

- Clear acceptance cues on support class ratings, bench geometry, water levels, and discharge quality help supervisors decide quickly, pause work when stability degrades, and document corrective actions, minimizing exposure time in the trench and maintaining production without sacrificing safety or quality.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Defined scope excludes utility testing and commissioning. The checklist focuses strictly on earthwork trenching with shoring or benching, safe access/egress, groundwater and stormwater management, and controlled backfill windows, aligning with approved project specifications and authority requirements for excavation and temporary works.

Pre-Excavation Planning

Shoring and Benching Setup

Access and Egress

Water Control and Stability

Excavation Operations

Backfill Windows and Closeout

Support Class Verification and System Setup

Selecting the correct support class is the foundation of safe trenching. Match the trench box or hydraulic shoring rating to soil type and expected depth from the geotechnical report. Before lowering equipment, inspect panels, struts, pins, and spreaders for damage; tag out anything bent, cracked, or leaking. Install supports to manufacturer spacing and sequence, then pressurize hydraulic struts gradually and record gauge readings. If benching is specified instead of shoring, confirm the bench geometry: measure angles with an inclinometer and step dimensions with a tape. Document all checks with photos along the trench at consistent intervals for traceability. Acceptance cues include a clean, plumb support line, verified pressure ranges, and benches within specified tolerance. Real jobsite practice: photograph model/serial plates, capture a close-up of each strut gauge, and log readings by chainage. These small, repeatable actions prevent collapses, minimize rework, and provide defensible records per approved project specifications and authority requirements.

- Record model, serial, and rating for every shoring system.

- Measure bench angles and steps against specification tolerances.

- Log hydraulic strut pressures within the stated safe range.

- Photograph supports at regular chainage intervals.

Safe Access, Egress, and Traffic Separation

Access planning reduces worker exposure time in the trench. Install secured ladders that extend above the landing per the project safety plan, and verify travel distance to an egress point meets plan requirements. Where personnel cross the trench, provide trench bridges or ramps with anti-slip surfaces and documented load ratings. Set edge protection and barricades to keep plant and pedestrians separated, and position spotters where plant operates near the trench lip. Maintain an exclusion zone and keep spoil at a safe offset to avoid surcharge loading on the trench wall. Acceptance cues include tied-off ladders with visible ID tags, measured egress distances, compliant ramp dimensions, and unbroken edge protection. Capture photos of each access point, a tape measurement for distance to egress, and the rating plate on bridges. These controls keep movements deliberate, prevent falls, and ensure that access remains safe as excavation progresses and support systems are adjusted.

- Secure ladders and verify extension height above landing.

- Measure travel distance to the nearest egress.

- Use rated bridges or ramps with anti-slip surfaces.

- Maintain continuous barricades and clear exclusion zones.

Water Control and Backfill Windows

Water undermines stability quickly, so implement the dewatering plan before deep cuts. Test-run pumps, confirm standby capacity, and install sediment control at discharge. Maintain the water level below trench formation and log staff gauge readings at intervals; use a turbidity meter to verify discharge clarity against project limits. Inspect for raveling, fissures, or base heave and pause work to correct if observed. Backfill windows are controlled time periods tied to approvals, weather, and site access. Confirm all hold-points are cleared, then begin backfill within the allowed window using specified material and moisture. Remove shoring progressively as lifts are placed to avoid voids. If the trench must remain open, plate or enhance barriers to protect the public and the works. Document timings, material tickets, moisture readings, and staged photos so the record shows exactly when and how stability was maintained.

- Log water levels and pump performance routinely.

- Verify discharge clarity with turbidity meter readings.

- Start backfill only after time-stamped approvals.

- Remove supports progressively while placing lifts.

How to Use This Interactive Trench Excavation Checklist

- Preparation: gather approved drawings, geotechnical report, dewatering plan, manufacturer data for shoring, GNSS/laser level, inclinometer, turbidity meter, pumps, barriers, ladders, PPE, and a camera-enabled device.

- Create a checklist instance: enter project, location, chainage, trench dimensions, soil type, intended support method (shoring or benching), and responsible supervisors/inspectors.

- Start interactive mode on site: tick items as completed, attach photos of measurements and gauges, and record readings (mm, degrees, kPa, NTU) directly in each item.

- Collaborate: tag team members in comments to resolve issues (e.g., pump sizing, bench geometry), log corrective actions, and re-verify with additional photos and signatures.

- Export and distribute: generate a commentable PDF or Excel export, include embedded photos and readings, and share with stakeholders for daily review.

- Sign-Off and archive: capture digital signatures from supervisor and inspector, lock the record, and store with QR authentication for audit retrieval.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Trench Excavation with Shoring/Benching

- Download PDF - Trench Excavation with Shoring/Benching

- View Image - Trench Excavation with Shoring/Benching