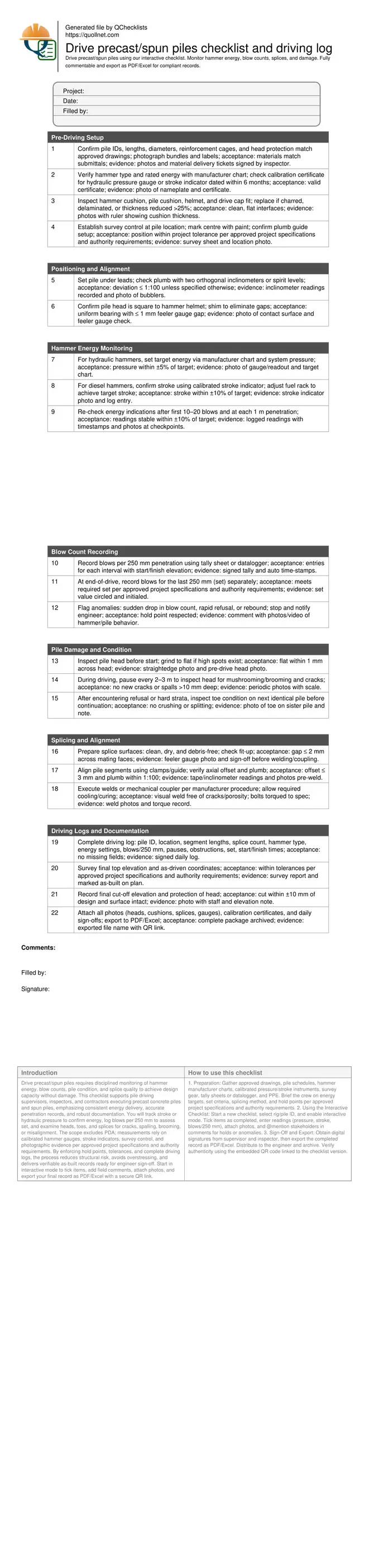

Drive precast/spun piles: inspection, energy, and driving logs

Definition: Drive precast/spun piles checklist guides site inspectors and supervisors to monitor hammer energy, blow counts, pile damage, splices, and driving logs for consistent, compliant foundation installations.

- Verify hammer energy settings and capture readings each driving interval.

- Record blows per 250 mm to confirm set and refusal criteria.

- Inspect heads, toes, and splices to prevent cracking and misalignment.

- Interactive, commentable checklist with export and QR code verification.

Drive precast/spun piles requires disciplined monitoring of hammer energy, blow counts, pile condition, and splice quality to achieve design capacity without damage. This checklist supports pile driving supervisors, inspectors, and contractors executing precast concrete piles and spun piles, emphasizing consistent energy delivery, accurate penetration records, and robust documentation. You will track stroke or hydraulic pressure to confirm energy, log blows per 250 mm to assess set, and examine heads, toes, and splices for cracks, spalling, brooming, or misalignment. The scope excludes PDA; measurements rely on calibrated hammer gauges, stroke indicators, survey control, and photographic evidence per approved project specifications and authority requirements. By enforcing hold points, tolerances, and complete driving logs, the process reduces structural risk, avoids overstressing, and delivers verifiable as-built records ready for engineer sign-off. Start in interactive mode to tick items, add field comments, attach photos, and export your final record as PDF/Excel with a secure QR link.

- Ensure reliable capacity by controlling hammer energy, cushion condition, and blow counts, while documenting penetration per 250 mm intervals. Early detection of damage and misalignment avoids overstress, rework, and rejected piles, giving the engineer confidence in end-of-drive acceptance and long-term performance.

- Raise productivity and traceability with disciplined splicing methods, survey-based alignment checks, and continuous logging of start/stop times, obstructions, set, and final cut-off levels. Consistent entries reduce disputes, accelerate approvals, and support timely completion of piling works across multiple rigs.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Strengthen compliance by using calibrated gauges, verified stroke settings, and photo evidence of pile heads, toes, helmets, and splices. Clear acceptance cues and hold points guide decisions to stop, adjust, or continue driving per approved project specifications and authority requirements.

Pre-Driving Setup

Positioning and Alignment

Hammer Energy Monitoring

Blow Count Recording

Pile Damage and Condition

Splicing and Alignment

Driving Logs and Documentation

Controlling Hammer Energy and Consistent Penetration Records

Reliable pile capacity starts with consistent energy transfer. Use the hammer manufacturer’s chart to translate required energy into hydraulic pressure or stroke, then verify with calibrated gauges or indicators. Reconfirm settings after the first 10–20 blows as cushions bed-in, and at regular penetration intervals. Record blows per 250 mm to assess set; sudden changes can expose soft pockets, obstructions, or cushion breakdown. Keep helmet interfaces clean and cushions fresh to avoid energy loss and head damage. When blow counts deviate from the expected trend, stop, document, and escalate. This repeatable approach prevents overstressing precast or spun piles and reduces disputes later. The goal is not just to hit refusal, but to arrive with documented evidence that the specified set was achieved with controlled energy delivery and acceptable alignment, resulting in dependable end-of-drive acceptance per approved project specifications and authority requirements.

- Translate target energy to pressure or stroke using manufacturer chart.

- Recheck energy after bedding-in and each 1 m of penetration.

- Record blows per 250 mm; isolate the final set interval.

- Stop and escalate on abnormal blow count trends.

- Maintain clean helmet and healthy cushions to limit losses.

Preventing Damage and Achieving Sound Splices

Precast and spun piles are strong yet brittle; damage often begins at the head from uneven bearing or degraded cushions. Square and smooth the head, keep pads intact, and pause during driving to inspect for brooming or spalling. At splices, cleanliness and tight fit-up are mandatory. Align segments to control eccentricity, clamp firmly, and verify plumb before welding or engaging mechanical couplers. Follow the manufacturer’s procedure for weld passes, torque values, and cooling or curing times. After completion, conduct a visual examination and photograph the splice. Poor prep or rushed splices cause cracks and cumulative misalignment that reduce axial capacity and increase bending demands. Treat each splice as a hold point with documented measurements; a few extra minutes here protects the entire foundation line and keeps acceptance straightforward for the engineer.

- Flat, clean head reduces stress concentrations and brooming.

- Replace cushions when thickness loss exceeds 25%.

- Splice fit-up gap ≤ 2 mm; offset ≤ 3 mm.

- Follow manufacturer splice and torque procedures.

- Photograph and sign off each completed splice.

Driving Logs, Survey Control, and Acceptance Cues

Complete logs are essential for acceptance and future troubleshooting. Each pile entry should include start/finish times, energy settings, blows per 250 mm, final set, obstructions encountered, splices made, and comments. Survey control ensures the pile starts in the right place and ends within positional tolerances; use calibrated instruments and record as-driven coordinates and top elevation. At the end, verify the cut-off level and protect the head. Pack the record with evidence: photos of gauges, cushions, heads, and splices, plus calibration certificates. Export the package for sign-off and archive it to maintain a consistent project trail. When logs are neat, measured, and photo-rich, approving engineers can validate capacity, alignment, and workmanship quickly, avoiding delays and rework while meeting approved project specifications and authority requirements.

- Log blows, set, energy, and time continuously.

- Survey initial position and final as-built coordinates.

- Verify cut-off elevation within ±10 mm of design.

- Attach gauge, cushion, head, and splice photos.

- Export and archive the signed daily package.

How to Use This Interactive Precast/Spun Pile Driving Checklist

- Preparation: Gather approved drawings, pile schedules, hammer manufacturer charts, calibrated pressure/stroke instruments, survey gear, tally sheets or datalogger, and PPE. Brief the crew on energy targets, set criteria, splicing method, and hold points per approved project specifications and authority requirements.

- Using the Interactive Checklist: Start a new checklist, select rig/pile ID, and enable interactive mode. Tick items as completed, enter readings (pressure, stroke, blows/250 mm), attach photos, and @mention stakeholders in comments for holds or anomalies.

- Sign-Off and Export: Obtain digital signatures from supervisor and inspector, then export the completed record as PDF/Excel. Distribute to the engineer and archive. Verify authenticity using the embedded QR code linked to the checklist version.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Precast/Spun Pile Driving Inspection

- Download PDF - Precast/Spun Pile Driving Inspection

- View Image - Precast/Spun Pile Driving Inspection