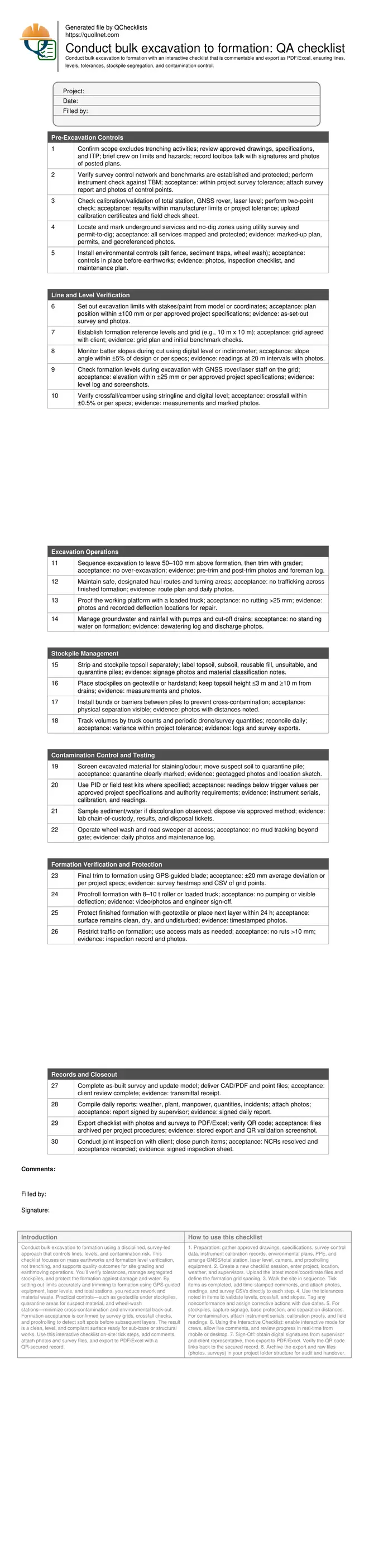

Conduct Bulk Excavation to Formation: QA Checklist

Definition: Conduct bulk excavation to formation with this field-ready checklist for contractors and inspectors, verifying lines, levels, tolerances, segregated stockpiles, contamination control, and photographic, survey-backed documentation.

- Confirms excavation limits, slopes, and formation levels within tolerance.

- Segregates stockpiles to preserve reuse and prevent cross-contamination.

- Controls contamination with screening, quarantine areas, and water management.

- Interactive, commentable, export, QR code verification for site records.

Conduct bulk excavation to formation using a disciplined, survey-led approach that controls lines, levels, and contamination risk. This checklist focuses on mass earthworks and formation level verification, not trenching, and supports quality outcomes for site grading and earthmoving operations. You’ll verify tolerances, manage segregated stockpiles, and protect the formation against damage and water. By setting out limits accurately and trimming to formation using GPS-guided equipment, laser levels, and total stations, you reduce rework and material waste. Practical controls—such as geotextile under stockpiles, quarantine areas for suspect material, and wheel-wash stations—minimize cross-contamination and environmental track-out. Formation acceptance is confirmed by survey grids, crossfall checks, and proofrolling to detect soft spots before subsequent layers. The result is a clean, level, and compliant surface ready for sub-base or structural works. Use this interactive checklist on-site: tick steps, add comments, attach photos and survey files, and export to PDF/Excel with a QR-secured record.

- This checklist provides a structured method to control bulk excavation boundaries, verify formation lines and levels, and document tolerances. It reduces rework by combining GPS/total-station set-out, grid-based surveys, and proofrolling to catch soft spots before placement of the next layer.

- Robust material handling guidance protects reuse value and the environment. Segregated stockpiles, geotextile hardstands, clear signage, and haul route controls prevent cross-contamination, while water and sediment management mitigate runoff or fines migration that could damage the formation or nearby receptors.

- Interactive online checklist with tick, comment, and export features secured by QR code.

- Contamination risk is actively managed with field screening, quarantine zones, and documented sampling per approved project specifications and authority requirements. Evidence includes calibrated readings, photos with location, and chain-of-custody records, supporting confident client sign-off.

Pre-Excavation Controls

Line and Level Verification

Excavation Operations

Stockpile Management

Contamination Control and Testing

Formation Verification and Protection

Records and Closeout

Survey control and tolerances at formation

Precise formation delivery starts with reliable control. Establish and protect benchmarks, then set out excavation limits and a level grid sized to the site’s variability. GNSS rovers and total stations allow rapid spot checks during excavation, while laser levels assist in trimming. A two-stage approach—bulk to near-grade, then fine trim—avoids over-excavation and protects bearing strata. Confirm linework, crossfall, and formation elevation using agreed tolerances, typically within ±20–25 mm for elevation and ±0.5% for crossfall, or as required per approved project specifications and authority requirements. Proofrolling validates uniform support where numbers alone can’t. Capture results in a simple heatmap of deviations and a log of any remedial trimming or backfilling. This evidence set—photos, survey CSVs, and sign-offs—supports client acceptance and reduces disputes by linking each check to calibrated instruments and approved control.

- Set a consistent survey grid and protect benchmarks.

- Trim in two stages to prevent over-excavation.

- Verify crossfall with stringline and digital level.

- Use proofrolling to reveal soft or pumping areas.

- Store survey CSVs and heatmaps with the checklist.

Stockpile segregation and haul management

Segregation preserves material value and prevents contaminant spread. Strip and store topsoil apart from subsoil and reusable fill, using geotextile or hardstand bases to prevent mixing with subgrade. Keep pile footprints compact, heights manageable, and clear of drains. Label every stockpile with origin, material class, and date. Bunds or barriers between piles prevent cross-contamination, and tarps reduce windblown fines. Control haul routes to keep traffic off finished formation, and schedule sweeping to avoid track-out. Reconcile truck counts with periodic survey volumes to keep production and reconciliation tight. Document each move with photos and location, so reused material has a reliable provenance when reintroduced. These steps reduce rework, improve sustainability metrics, and maintain a clean, buildable formation ready for subsequent layers.

- Separate topsoil, subsoil, reusable fill, and quarantine piles.

- Place piles on geotextile or hardstand bases.

- Keep piles away from drains and protected by bunds.

- Label piles with material class and origin.

- Reconcile volumes via truck counts and surveys.

Contamination control and formation protection

Contamination control starts with awareness. Train operators to flag discoloration or odours and move suspect soil to a clearly marked quarantine pile. Where required, take field readings and sample for lab confirmation per approved project specifications and authority requirements. Manage water by diverting clean runoff, pumping ponded water, and filtering discharge to prevent fines migration. Keep wheel wash functional to protect public roads and avoid enforcement actions. Once trimmed, protect the formation by limiting traffic, placing geotextile, or advancing the next layer rapidly. A short exposure window—ideally within a day—minimizes moisture swings and surface damage. Proofroll the finished formation to find soft spots, repair immediately, and recheck. Maintain a clean photographic record and attach calibrated readings so acceptance is traceable and defensible.

- Quarantine suspect soil and label clearly.

- Use field screening where specified and record readings.

- Manage water to avoid standing water on formation.

- Limit trafficking on finished formation surfaces.

- Proofroll, repair soft spots, and re-verify.

How to use this bulk excavation interactive checklist

- Preparation: gather approved drawings, specifications, survey control data, instrument calibration records, environmental plans, PPE, and arrange GNSS/total station, laser level, camera, and proofrolling equipment.

- Create a new checklist session, enter project, location, weather, and supervisors. Upload the latest model/coordinate files and define the formation grid spacing.

- Walk the site in sequence. Tick items as completed, add time-stamped comments, and attach photos, readings, and survey CSVs directly to each step.

- Use the tolerances noted in items to validate levels, crossfall, and slopes. Tag any nonconformance and assign corrective actions with due dates.

- For stockpiles, capture signage, base protection, and separation distances. For contamination, attach instrument serials, calibration proofs, and field readings.

- Using the Interactive Checklist: enable interactive mode for crews, allow live comments, and review progress in real-time from mobile or desktop.

- Sign-Off: obtain digital signatures from supervisor and client representative, then export to PDF/Excel. Verify the QR code links back to the secured record.

- Archive the export and raw files (photos, surveys) in your project folder structure for audit and handover.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Bulk Excavation to Formation Inspection

- Download PDF - Bulk Excavation to Formation Inspection

- View Image - Bulk Excavation to Formation Inspection