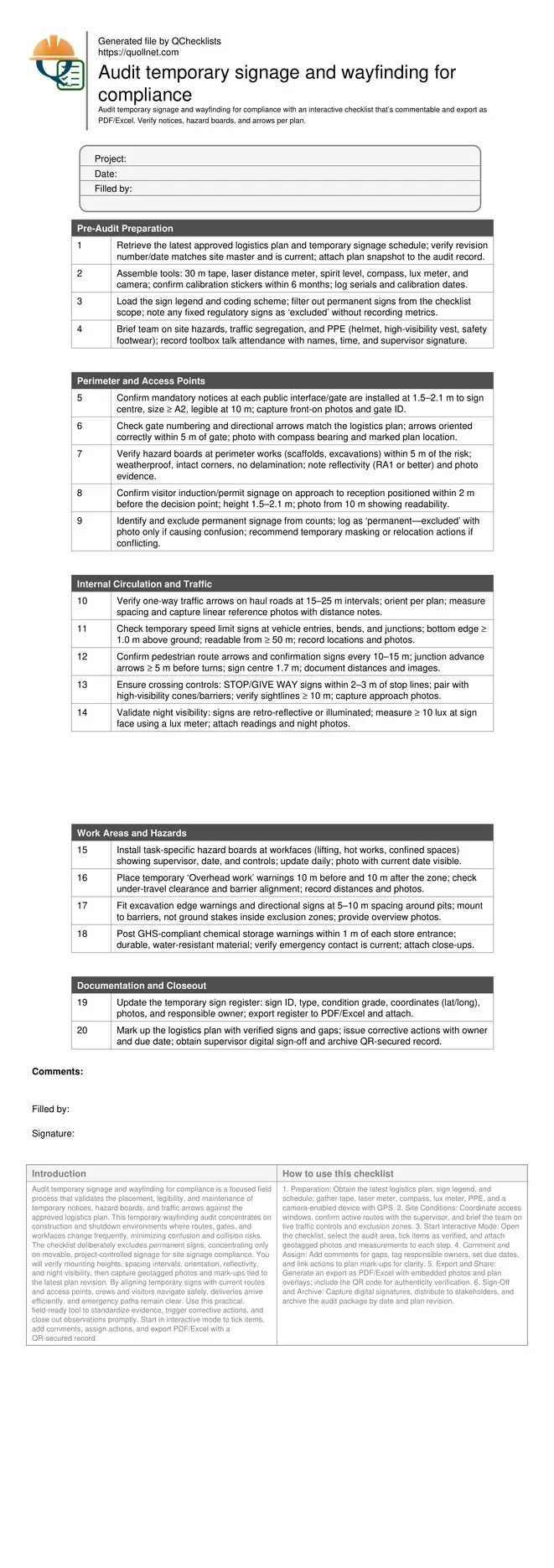

Temporary Signage and Wayfinding Compliance Audit Checklist

Definition: Audit temporary signage and wayfinding for compliance helps site managers verify mandatory notices, hazard boards, and traffic arrows align with the logistics plan, excluding permanent signage.

- Confirm temporary notices, arrows, and hazard boards follow the logistics plan.

- Reduce confusion, near-misses, and delays with consistent, visible temporary wayfinding.

- Use measured placement, reflectivity, and visibility checks with photo evidence.

- Interactive, commentable checklist with export and QR code verification.

Audit temporary signage and wayfinding for compliance is a focused field process that validates the placement, legibility, and maintenance of temporary notices, hazard boards, and traffic arrows against the approved logistics plan. This temporary wayfinding audit concentrates on construction and shutdown environments where routes, gates, and workfaces change frequently, minimizing confusion and collision risks. The checklist deliberately excludes permanent signs, concentrating only on movable, project-controlled signage for site signage compliance. You will verify mounting heights, spacing intervals, orientation, reflectivity, and night visibility, then capture geotagged photos and mark-ups tied to the latest plan revision. By aligning temporary signs with current routes and access points, crews and visitors navigate safely, deliveries arrive efficiently, and emergency paths remain clear. Use this practical, field-ready tool to standardize evidence, trigger corrective actions, and close out observations promptly. Start in interactive mode to tick items, add comments, assign actions, and export PDF/Excel with a QR-secured record.

- Verify temporary site signage against the latest logistics plan, confirming locations, heights, spacing, and orientations while excluding permanent signs. Capture geotagged photos, annotate plans, and record responsible parties for prompt correction.

- Improve safety and flow by validating mandatory notices at gates, hazard boards at workfaces, and directional arrows on haul roads and pedestrian routes. Standardized placement reduces uncertainty, avoids conflicting cues, and supports emergency access.

- Record objective evidence: distances in metres, mounting heights, reflectivity grades, and night visibility in lux. Maintain a sign inventory with IDs, coordinates, condition, photos, and sign-off to support audits and traceability.

- Interactive online checklist with tick, comment, and export features secured by QR code. Export as PDF/Excel for distribution, archive revisions, and share corrective actions with contractors and supervisors in real time.

Pre-Audit Preparation

Perimeter and Access Points

Internal Circulation and Traffic

Work Areas and Hazards

Documentation and Closeout

Scope, Boundaries, and Risk Control

This checklist focuses strictly on temporary signage and wayfinding that the project controls: mandatory notices, hazard boards, and directional arrows shown on the current logistics plan. It excludes permanent signs, which are outside the project’s temporary control but may be flagged only if they conflict with temporary routing. Common risks include mixed messages at gates, missing warnings at active workfaces, and arrows that no longer reflect changed traffic patterns. Auditors should walk flows in both directions, validating decision points where people choose routes. Evidence requirements include measured distances in metres, mounting heights, reflectivity or lighting adequacy, and geotagged, time-stamped photos. Use plan mark-ups to compare as-built placement against the latest revision. Actions must state the responsible person and due date, and updates should be verified in the next walkdown.

- Audit only temporary, project-controlled signage.

- Flag conflicting permanent signs as excluded.

- Walk flows in both directions and validate decisions.

- Capture geotagged, time-stamped photo evidence.

- Assign actions with owners and due dates.

Placement Methods and Acceptance Cues

Consistent placement makes temporary routes readable under pressure. Aim for 1.5–2.1 m to the centre of pedestrian-facing signs and a bottom edge of at least 1.0 m for vehicle-facing signage. Use intervals of 10–15 m for pedestrian arrows and 15–25 m for vehicle arrows, increasing density at junctions and poor sightlines. Validate orientation against the logistics plan, not memory. Ensure materials are durable, weatherproof, and retro-reflective or illuminated for night operations; target a minimum of 10 lux on sign faces if using lighting. Secure signs to stable supports, avoiding trip hazards or intrusion into clearances. Replace damaged or faded boards immediately. Use plan mark-ups to record exact positions and narrative notes to explain deviations approved by the supervisor, per approved project specifications and authority requirements.

- Maintain consistent heights for readability.

- Use measured spacing intervals by route type.

- Confirm orientation against the plan.

- Ensure reflectivity or lighting at night.

- Secure mounts without creating hazards.

Evidence, Traceability, and Closeout

Evidence should prove that installation meets the logistics plan and site requirements. Take overview photos from approach lines and close-ups of mounting and content. Log coordinates using a smartphone or GPS, attach distances and lux readings, and note sign IDs. Maintain a register that includes type, condition, and owner for maintenance. When gaps or conflicts arise, raise corrective actions with clear locations, references, and deadlines. Close the loop by re-inspecting and documenting the fix. Archive each audit as a dated package with the plan, register, photos, and sign-offs. Use QR-secured exports so anyone scanning can confirm authenticity and the exact revision audited, supporting handovers and regulatory inspections without ambiguity.

- Capture overview and close-up photos.

- Record coordinates and measurements.

- Maintain a detailed sign register.

- Issue actions with deadlines and owners.

- Archive audits with QR-secured exports.

How to Run the Temporary Signage and Wayfinding Audit

- Preparation: Obtain the latest logistics plan, sign legend, and schedule; gather tape, laser meter, compass, lux meter, PPE, and a camera-enabled device with GPS.

- Site Conditions: Coordinate access windows, confirm active routes with the supervisor, and brief the team on live traffic controls and exclusion zones.

- Start Interactive Mode: Open the checklist, select the audit area, tick items as verified, and attach geotagged photos and measurements to each step.

- Comment and Assign: Add comments for gaps, tag responsible owners, set due dates, and link actions to plan mark-ups for clarity.

- Export and Share: Generate an export as PDF/Excel with embedded photos and plan overlays; include the QR code for authenticity verification.

- Sign-Off and Archive: Capture digital signatures, distribute to stakeholders, and archive the audit package by date and plan revision.

Call to Action

- Start Checklist Tick off tasks, leave comments on items or the whole form, and export your completed report to PDF or Excel—with a built-in QR code for authenticity.

- Download Excel - Temporary Signage and Wayfinding Audit

- Download PDF - Temporary Signage and Wayfinding Audit

- View Image - Temporary Signage and Wayfinding Audit